The data center industry is changing. Multiple external forces have come together that are accelerating demand for new data centers while simultaneously creating roadblocks to their construction.

Understanding Data Center Construction Challenges

Increased labor and raw material costs coupled with supply chain issues hamper construction. Prime space for data centers in major market’s is harder to come by and more expensive. Builders are turning to secondary markets to compensate but are encountering resistance from residents due to concerns of significant land, water, and power consumption at their expense.

Communities fear that resource consumption will only increase as data centers install more power-hungry, heat producing high-performance computing (HPC) systems needed to run today’s AI and ML applications.

This article examines several of the toughest challenges data center builders face and how Snake Tray cable conveyance solutions can help overcome obstacles to construction.

- Supply chain issues. A year after officially declaring the end of the pandemic many supply chains remain broken. Overseas manufacturers are unreliable, still filling back orders and subject to unexpected closures, while international shipping remains a mess. Contractors can wait weeks beyond promised delivery dates for materials, causing construction delays and inflating expenses. Once the parts needed for cable conveyance arrive on site, segments of generic basket tray must be fabricated by expensive skilled laborers into every turn, TEE, cross, and elevation change needed for the project.

Most cable conveyance manufacturers are based in Europe, Mexico, or China. Snake Tray is the only 100% domestic manufacturer of an entire ecosystem of cable management products. Snake Tray qualifies for the Buy American Act, producing everything it sells at its Long Island, New York facilities, with all products manufactured from US-sourced recycled steel. Snake Tray has warehouses throughout the country stocked with standard prefabricated cable tray components (including turns, TEEs, crosses, and elevation changes) ready for immediate delivery and speedy installation, eliminating the supply chain headaches of international sourcing as well as the expenses of on-site fabrication.

- Accelerated construction using modern, modular design. Hyperscale data centers are being built at a record pace to meet increasing demand (even in the face of many challenges). As such, many data center builders have templated their designs to construct modular facilities in cookie-cutter fashion. Inside are row after row of server cabinets, all meticulously planned, identically sized, and spaced. This standardization allows engineers to precisely calculate material needs and reduce expenses over multiple sites. To lower the cost of cooling these giant spaces many data centers evolved from mesh wire cages and cooling the entire room to building enclosed containment rooms (pictured). Some are equipped with advanced water-cooled systems, others pump cold air into each room via ductwork and exhaust vents. But all are designed with identical egress points and pathways for running the low voltage and data cables that connect to the hardware in each room. Most competitors ship a quantity of 10-foot straight aluminum ladder or basket tray sections and leave it to installers to fabricate the pathways and fittings for each room on site.

Working in partnership with project engineers, Snake Tray designs and manufactures cable conveyance kits customized to the exact specifications of a containment room. Each containment room receives an identical package of prefabricated 801 Series Mega Snake® components with all the sections and turns measured and pre-cut for installers to quickly mount in each room and connect cables to the main trunk lines. The Mega Snake offers a load capacity equal to an aluminum ladder but at a basket tray price point. If using a raised flooring system, the 301 Series Snake Canyon® integrates with any type of access floor to create a concealed cable pathway under the floor to route cables directly into each containment room. There are no special tools, accessories, or skills required, allowing for fast and easy deployment and slashing labor costs by eliminating field fabrication. Containment rooms are quickly ready to be loaded with the hardware and cables needed to go online.

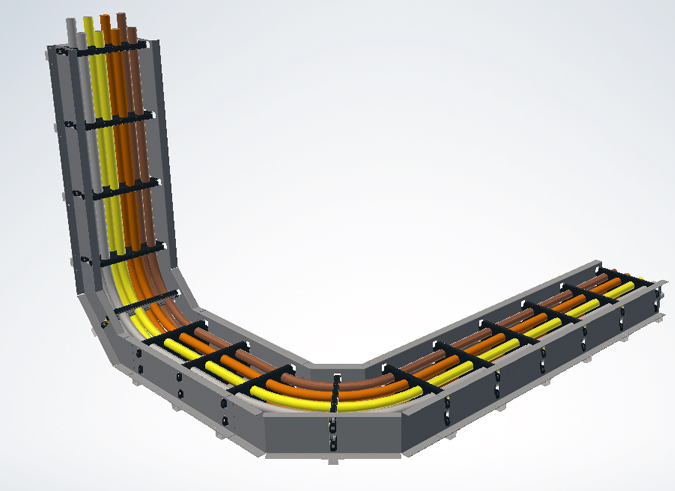

Working in partnership with project engineers, Snake Tray designs and manufactures cable conveyance kits customized to the exact specifications of a containment room. Each containment room receives an identical package of prefabricated 801 Series Mega Snake® components with all the sections and turns measured and pre-cut for installers to quickly mount in each room and connect cables to the main trunk lines. The Mega Snake offers a load capacity equal to an aluminum ladder but at a basket tray price point. If using a raised flooring system, the 301 Series Snake Canyon® integrates with any type of access floor to create a concealed cable pathway under the floor to route cables directly into each containment room. There are no special tools, accessories, or skills required, allowing for fast and easy deployment and slashing labor costs by eliminating field fabrication. Containment rooms are quickly ready to be loaded with the hardware and cables needed to go online. - Increased power requirements of AI computing. AI computing increases energy consumption by a magnitude of four over traditional data center computing activities. Whereas most existing data centers currently are running banks of 100 to 200 Kcmil cables inside the structure to power server racks, they will need to upgrade to 400 to 800 Kcmil cables at the utility connection point – or larger if the cables are touching to offset derate – to power AI/ML operations. That’s a lot more weight to carry, a lot more cables to organize, and a lot more electrons that will be converted into wasted heat if the cables are not properly separated, costing even more to cable and cool today’s AI-enabled data center. Another option is needed besides giant, heavy duty cable trays or an enclosed cable bus. Cable buses are custom built for each project, take time to fabricate, and are extremely expensive.

The Snake Max for AI Data Centers is the industry’s only free-air cable management system specifically designed to meet the demands of conveying high ampacity cables inside and outside the data center to support AI/ML computing. Prefabricated components make installation fast and affordable. Insulated cable separators called clicks easily attach to lightweight aluminum side rails to maintain uniform cable spacing, allowing the heat of electrical friction to dissipate into the surrounding air and eliminating the need to derate cables. The system accommodates multiple layers of cables up to 1250 Kcmil and holds them all in a small footprint to organize and route cables in tight indoor spaces.

The Snake Max for AI Data Centers is the industry’s only free-air cable management system specifically designed to meet the demands of conveying high ampacity cables inside and outside the data center to support AI/ML computing. Prefabricated components make installation fast and affordable. Insulated cable separators called clicks easily attach to lightweight aluminum side rails to maintain uniform cable spacing, allowing the heat of electrical friction to dissipate into the surrounding air and eliminating the need to derate cables. The system accommodates multiple layers of cables up to 1250 Kcmil and holds them all in a small footprint to organize and route cables in tight indoor spaces. - Overcoming utility capacity limitations. Some utilities simply cannot provide 100% of the capacity needed to power and cool today’s AI-enabled hyperscale data center, especially in secondary markets. In fact, some utilities have capped power consumption for data center customers. Other locations are too far from the utility to build a high-capacity power transmission network. To compensate, data centers are buying larger lots and constructing private power plants adjacent to their facilities. Some are fossil fuel-powered generators, others use renewable wind and solar power, a few are looking at hydrogen fuel cells for both primary and secondary power. Then there’s the real estate on the roof. Many data centers are installing rooftop solar arrays, taking advantage of thousands of square feet of unobstructed space for on-site green energy production and offset energy costs.

Whatever source is used to generate electricity adjacent to or on the data center, it must be harnessed and channeled into a connection box, AC inverter, or battery array. The family of utility-grade Solar Snake Max XL products (top) allows for efficient above ground construction of free-air cable conveyance for high ampacity cables running from adjacent power sources to the data center. For rooftop solar installations, the 407 Series Solar Snake Tray or 801 Series Mega Snake are ideal solutions. The 407 Series Solar Snake Tray is a hand bendable cable conveyance system featuring a patented lobster-trap design that quickly and securely carries DC circuitry from rooftop solar panels to their terminations, helping transform previously wasted space into an energy producing asset. The 801 Mega Snake Series has prefabricated sections to make rooftop installations quick and easy. There’s a variety of rooftop mounting options to accommodate any style of roof.

Whatever source is used to generate electricity adjacent to or on the data center, it must be harnessed and channeled into a connection box, AC inverter, or battery array. The family of utility-grade Solar Snake Max XL products (top) allows for efficient above ground construction of free-air cable conveyance for high ampacity cables running from adjacent power sources to the data center. For rooftop solar installations, the 407 Series Solar Snake Tray or 801 Series Mega Snake are ideal solutions. The 407 Series Solar Snake Tray is a hand bendable cable conveyance system featuring a patented lobster-trap design that quickly and securely carries DC circuitry from rooftop solar panels to their terminations, helping transform previously wasted space into an energy producing asset. The 801 Mega Snake Series has prefabricated sections to make rooftop installations quick and easy. There’s a variety of rooftop mounting options to accommodate any style of roof.

Snake Tray Solutions for Data Center Construction Challenges

Certainly, there are other challenges to the efficient construction of AI-enabled data centers, and this article highlights just a few relating to cable management. But perhaps more than any other structure, cables are the lifeblood and nervous system of a data center, and the cable management systems is its backbone.

At Snake Tray, cable conveyance for data and power is our wheelhouse. Using our innovative expertise as an extension of your engineering team we can solve any problem.

Contact us to learn more about how the Snake Tray family of cable management solutions can bring your data center into the age of AI.