This IS your father’s Oldsmobile. Steel cable runways have been a staple of telecommunications rooms, data centers, and other highly-cabled facilities for generations. While other cable management solutions have since arrived on the scene that offer more flexibility and higher loading capacities while requiring less labor and lowering costs, (like the Snake Tray 801 Series Mega Snake®, a topic for another blog), steel cable runways remain popular in many telco installations. Why? Because that’s the way it has always been.

Your predecessor ordered steel cable runways when he was in charge, as did his Baby Bell boss before him, and his AT&T boss before him. Now it’s your turn to call the shots, and you’re going to stick with a tried-and-true solution. Nothing wrong with that.

Steel cable runways are another commodity cable management product, much like aluminum cable trays. They are available from a number of manufacturers, and they all do pretty much the same thing: keep power, data and telecommunications cables organized as they run from trunk to panel. Made from tubular steel, cable runways deliver maximum strength and support. Some can carry loads up to 130 pounds per linear foot when supported every five feet. Generally less expensive than aluminum cable trays, the differences are that steel runways are constructed in a flat ladder style—there are no side rails—and they are usually only available in widths up to 36 inches (aluminum trays can be up to 60″ wide). This reduces capacity as cables can only be pyramided so high before they fall off the sides of the tray. Therefore most steel runways today are found in smaller telecommunications rooms and closets where the volume of cables can be handled by a flat tray, but the weight per foot is beyond what a generic basket tray could support.

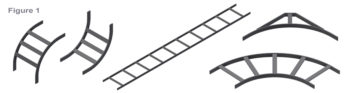

Also like aluminum cable trays, steel cable runways are not hand-bendable. Components arrive in prefabricated straight sections, 90° turns, and vertical bends to manage elevation changes and drops (Figure 1 ). They easily connect to each other, and can be suspended from ceilings, attached to walls, or bolted to a row of cabinets with the proper splice kits and mounting accessories.

So why should you choose Snake Tray’s 610 Series Steel Cable Runway rather than a competitive brand for your next cabling project? From a functional perspective, there’s not much difference between them, (although we do offer a Rapid Ship Cable Runway Kit consisting of two five-foot sections of runway and a butt splice kit that meets UPS shipping requirements without additional charges). Our runways are made from tubular steel and carry cable loads up to the industry standard of 130 pounds per linear foot when supported every five feet, just like our competitors. The 610 Series is competitively priced, easy to install, and available in a wide range of sizes and widths, also just like our competitors, BUT…

- Snake Tray is located on Long Island, New York, making it the only manufacturer of steel cable runways in the northeast United States. That equates to reduced lead time, faster delivery, and reduced shipping costs.

- Snake Tray is the designer and manufacturer. You deal directly with the source, not a third party contract manufacturer; we are able to handle customized orders and non-standard widths with the same speed and cost-effectiveness as stock products. Snake Tray can usually fulfill your order in roughly half the time of our competitors.

- Snake Tray is the only provider of modular power distribution modules for steel cable runways. Terminate power cables wherever needed with a modular NEMA connection, and then easily plug in various machines around the room from localized power drops.

- Snake Tray is a one-stop shop for all of your cable management needs. Chances are your cabling project will require more than steel cable runways. You might need hand-bendable trays, risers, under floor trays, power distribution solutions, or prefabricated wire baskets to complete the job. Why deal with multiple vendors when you can partner with just one? Snake Tray has it all, including the transitions and adapters to route cables off and onto steel cable runways as well as between any type of cable management system.

Snake Tray offers its 610 Series Steel Cable Runway to round out its product line to accommodate customer needs for maximum strength applications in data centers, telecommunication rooms, and other cable-intensive environments. While functionally identical to most generic steel cable runways, only Snake Tray delivers the added value of local manufacturing for fast turnaround and reduced shipping costs, integrated power distribution modules, plus the convenience of a single solution provider for all of your data cabling and power distribution needs.

Snake Tray has revolutionized the data and power distribution market with cable management, power distribution systems and enclosures all designed to install quickly, reduce labor and material costs, and significantly drive down the total cost of construction. If you would like to learn more, visit us at snaketray.com. Our engineers and sales teams stand ready to help execute your next cabling project with maximum efficiency and profitability.