Raised access flooring (RAF) offers a number of environmental and layout flexibility advantages in large commercial and professional spaces, chief among them is the ability to install under floor electrical distribution systems to discreetly bring power and data to every point of need.

Once the decision to use RAF is made, there’s really only one choice when it comes to under floor power distribution: Snake Tray‘s Snake Bus®.

In this article we’ll take a deep dive into the Snake Bus modular power distribution system, showcasing its revolutionary approach to electrical infrastructure and how it enables architects and engineers to capitalize on the advantages of RAF outside traditional data center environments. We’ll highlight the system’s cost efficiency, flexibility, and compliance benefits, particularly with regard to energy regulations like California’s Title 24, and point you to some real-world use cases and resources for greater insights along the way. In fact, you might find the proof so compelling you’ll make the decision to go with Snake Bus under floor power distribution first and enjoy the environmental benefits of RAF as a byproduct!

Chapter 1: Understanding the Snake Bus® Power Distribution System

What is the Snake Bus Under Floor Power Distribution System?

Snake Tray’s prefabricated Snake Bus power distribution system is the fastest, easiest, and most cost-effective way to wire any commercial space from 1,000 to 1,000,000 square feet. Snake Bus is compatible with all post and panel raised access floor systems – even ultra-low cellular floors – and is completely reusable and removable. Installation is so easy and intuitive it saves in excess of 30% on total installed costs versus competitive systems.

Snake Tray’s prefabricated Snake Bus power distribution system is the fastest, easiest, and most cost-effective way to wire any commercial space from 1,000 to 1,000,000 square feet. Snake Bus is compatible with all post and panel raised access floor systems – even ultra-low cellular floors – and is completely reusable and removable. Installation is so easy and intuitive it saves in excess of 30% on total installed costs versus competitive systems.

Snake Bus delivers infinite flexibility during the construction process to allow contractors to complete installations on time and under budget. Post-construction, it gives property owners the ability to execute moves, adds, and changes to the power distribution layout as needed.

The unique Snake Bus system uses bus bar technology instead of copper wire and conduits to provide 50 Amp, three-phase, 208 Volt service for up to 18 Kilowatts of power wherever it is needed in one easy-to-install track – that’s three times the power of conventional systems. More energy efficient than traditional wiring, Snake Bus uses 30% less copper and experiences less voltage drop over long runs, further reducing energy consumption. Talk about being GREEN!

Multiple phases built into each Snake Bus track allow for one or two circuits to be designated as a variable power circuit to support energy conservation mechanisms and growing compliance standards like California’s Title 24.

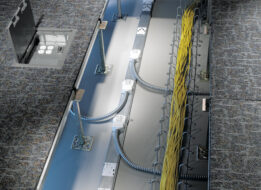

Tap offs (called Snake Whips) deliver power at precise locations by connecting recessed enclosure boxes to receptacles positioned every 12 inches along the Snake Bus track for ultimate flexibility. Modular connectors lock into position in 10 seconds. Need to move an enclosure? Simply swap a solid floor tile or air vent panel for a recessed enclosure box at the desired position and plug the Snake Whip into the nearest receptacle.

Read this article to learn why Snake Bus is the best power distribution system for use with RAF.

Related Article:

Snake Bus: The BEST Power Distribution System for Under Raised Access Floors

Primary Snake Bus Components

The Snake Bus system consists of several modular components that snap together in seconds to create a smart power distribution system that requires less time, labor, and skill to install:

- Snake Bus Feed Module: Connects the beginning of the track to the building’s main electrical system to energize the system.

- Snake Bus Track: 4-foot and 8-foot-long track segments featuring bus bar technology distribute up to 50 Amps of power. The modular sections securely connect to one another and lock into place. Each has grounded power receptacles positioned every 12 inches and integrated mounting brackets to fix the track to the subfloor. Two-phase and three-phase versions are available (see Technical Insights & Compliance).

- Interlink Module: Allows for fast changes in any direction between track segments or to easily snake around and over obstacles under the RAF.

- Snake Whips: Modular tap offs deliver power to individual offices and workstations by snapping into a track receptacle at the desired location. Tap off can be preconfigured to the electrical requirements of the devices to be connected, and can be up to 25 feet long for increased flexibility. A number of accessories such as under desk power modules and rack mount power units with modular Snake Whip connectors are available.

- Recessed Power & Data Enclosures: Each unique User Interface Unit contains the required mix of power receptacles, circuit breakers, and data ports that bring electricity and connectivity to the surface. Snake Tray offers a complete line of recessed enclosures that can match the décor and sit flush with RAF tiles. Learn more about our floor enclosures here.

Get our white paper, Snake Tray® Snake Bus®: Revolutionizing Under Floor Power Distribution, to learn more about how our under floor power distribution components contribute to energy efficiency, sustainability, and overall cost savings.

Chapter 2: Snake Bus Applications & Case Studies

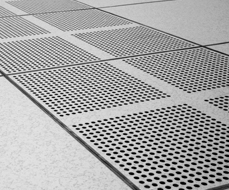

Think about Raised Access Floors and what comes to mind for most of us are the drab gray ventilated steel plates used to cool computers in data centers. While still true, there has been a renaissance in RAF due to several cost and environmental factors.

Think about Raised Access Floors and what comes to mind for most of us are the drab gray ventilated steel plates used to cool computers in data centers. While still true, there has been a renaissance in RAF due to several cost and environmental factors.

Today, raised access floor panels are available in a multitude of colors and finishes to integrate with any design concept. Many are made using sustainable materials for a green design and LEED certification, bringing RAF out of the data center and into all types of high traffic areas like call centers, trading floors, museums, art galleries, hotel and corporate lobbies, libraries, casinos, command centers, and similar spaces where flexible power distribution and/or data connectivity is required.

In fact, some of them can be quite stunning. You might not realize you are walking on a RAF until you see a floor tile lifted to access the power distribution and connectivity systems concealed below.

Architects and engineers are interested in RAF for a number of reasons, but mostly because of the layout flexibility it offers during and after project completion. For aesthetic purposes, they want the top of the enclosures to be indistinguishable from surrounding RAF panels, and perfectly flush with them to avoid a tripping hazard when not in use. Examples of common applications include:

Architects and engineers are interested in RAF for a number of reasons, but mostly because of the layout flexibility it offers during and after project completion. For aesthetic purposes, they want the top of the enclosures to be indistinguishable from surrounding RAF panels, and perfectly flush with them to avoid a tripping hazard when not in use. Examples of common applications include:

- fast and easy rearrangement of cubicles, workstations, and conference rooms as more employees return to the office

- expanding capacity like adding more slot machines in a casino or additional monitors in a command center

- quickly reconfigure retail spaces for new tenants or spaces used for temporary or fluid events such as trade shows, art galleries, and museum exhibits

- eliminates the use of HVAC ductwork in favor of low pressure forced air to improve air quality and reduce material costs

Get our white paper, Build Flexibility into Office Design with Snake Tray®, to learn more about how Snake Bus contributes to a healthier office environment while increasing layout flexibility.

Snake Bus in the Real World

Snake Tray has recently completed the design, manufacturing, and delivery of two major Snake Bus systems for under RAF electrification, each representing very different applications.

In New York City, 17 floors of a new 58-story skyscraper will soon be home to one of the world’s largest financial institutions. Fifteen of those floors have RAF with the Snake Bus power distribution system installed underneath. Read the case study, Snake Bus Powers Major Financial Services Group’s New Financial Headquarters, to learn how Snake Tray helped electrical contractors overcome supply chain issues caused by the pandemic, reduce labor and material costs, and recoup lost time to bring the project to a successful close.

In Los Angeles, the new Lucas Museum of Narrative Art is a 300,000 square feet space dedicated to the contributions of its movie-making mogul namesake, George Lucas. Many of the exhibits are interactive and require power and/or connectivity, and pieces are being constantly moved, changed, and replaced. Read the case study, Snake Tray to Power Exhibits at Lucas Museum of Narrative Art, to learn how the Snake Bus power distribution system allows curators to freely move free standing exhibits and discreetly connect them without exposing AC and networking infrastructure to visitors.

Related Article:

Snake Tray to Power Exhibits at Lucas Museum of Narrative Art

Chapter 3: Snake Bus Benefits & Advantages

Wiring commercial spaces for power and/or data is perhaps one of the costliest and labor-intensive aspects of any construction project. Pulling copper through mounted conduit and stub-ups requires expensive skilled labor and is time consuming. Electricians must strip wires and terminate every connection manually.

The terminations are at fixed positions – either inside walls or at measured distances on the floor – making moves, adds, and changes messy and difficult. The traditional pipe and wire method consumes more copper, requires all kinds of accessories like connection boxes, outlets, and circuit breakers on every line, creates waste, and makes it complicated to support energy conservation mandates.

The Snake Tray Snake Bus Power Distribution System used in conjunction with raised access flooring eliminates these issues and provides a wide range of benefits that can be organized into three categories:

Flexibility & Scalability

- Lay tracks in any pattern or position to create a customized power distribution system with unlimited design flexibility

- Build a smart power distribution system from 1,000 up to 1,000,000 square feet

- Make adds, changes, and moves as needed; quickly reconfigure office and retail spaces for new tenants at minimal expense

- Modular tracks and Snake Whips snap together with Lego™-like ease and speed

- Compatible with all post and panel raised floor systems, as well as low profile access floors at just 2.5 inches tall

Read more about the advantages of a raised floor cable management system here.

Related Article:

Cost, Material, & Energy Efficiencies

- All components are pre-manufactured to speed installation, saving in excess of 30% on the total installed project costs.

- All connections are modular, eliminating on-site fabrication, wire stripping, and attaching individual cable terminations

- Bus bar technology uses approximately 30% less copper than traditional wiring methods and experiences less voltage drop which can save on energy consumption

- Delivers up to 18 Kilowatts of power via its 50 Amp, 3-Phase 208 Volt solution in one easy to install track – up to three times that of competing under floor power distribution systems – to support more devices with less infrastructure

- In multi-story buildings, Snake Bus used with RAF lowers typical slab-to-slab height by one to two feet per floor, drastically reducing core and shell material needs while maintaining optimal ceiling height

Environmental & Functional

- Sleek, low-profile tracks do not impact air flow of under floor pressurized climate control systems to improve indoor air quality

- Eliminates the need for unsightly conduit on vertical exterior surfaces

- Snake Bus used with under floor climate control allows for taller ceiling heights which in turn allow for larger windows, enhancing natural lighting

- Allows free-standing exhibits, kiosks, and trade show booths to access power and connectivity without exposing infrastructure

- Integrates with building management systems (BMS) to enable energy conservation measures with a variable power circuit to de-energize non-essential equipment

- Provides both the equipment and isolated earth ground in one single system

- Completely reusable, moveable, and recyclable, Snake Bus produces zero waste

Related Article:

Snake Bus: The BEST Power Distribution System for Under Raised Access Floors

Chapter 4: Technical Insights & Compliance

Perhaps one of the biggest advantages of Snake Bus is its ability to support energy conservation standards. This section will talk about California Title 24 compliance and some internal technical innovations key to Snake Bus’s performance.

What is Title 24 and how does Snake Bus help with compliance?

California Title 24 requires builders to meet a number of standards for energy conservation and sustainable material use in new construction. The standards affect everything from window and door operation to climate control and lighting efficiencies, roofing materials, and electricity consumption. The incentives are financial rewards for compliance and penalties for non-compliance. The basic tenants of Title 24 have been emulated by many other states. This has given rise to an entire industry focused on eco-friendly design and automated building management systems (BMS) that make our buildings smarter and environments healthier.

In a nutshell, BMS technology uses timers and occupancy sensors to determine when an area or room is active and needs power. BMS sensors can detect when a person has entered a conference room, is walking down a hallway, or when they leave their desk, for example. At large industrial/commercial facilities, BMS can be linked to power distribution systems running underneath raised access flooring to better monitor and manage electricity usage at individual workstations.

This article is a quick read on Title 24 and how BMS sensors work.

When it comes to electrical power systems and appliances, Title 24 basically says that any piece of non-essential equipment like monitors, fans, lights, and printers must be completely shut down when not in use in order to maximize energy savings. Many devices, even when turned off, still draw milliwatts of current when plugged into a live outlet.

The Snake Bus system assists with Title 24 compliance through the automatic disengagement of non-essential electrical loads and devices in an office environment when the space is not in use. It uses multi-phase technology with at least one phase designated as a variable circuit connected to the BMS. Any device plugged into an outlet on that circuit can be de-energized as needed by the occupancy sensors and will draw zero watts. The value of Snake Bus here lies in the daily milli-watt savings multiplied over the thousands of devices plugged into a power distribution system in a large corporate or industrial environment.

Snake Tray offer two types of 50 Amp Snake Bus Systems, both offering Title 24 compliance and compatible with the same enclosures and accessories:

For larger structures, the three-phase 707 Series Snake Bus provides up to 18 Kilowatts of power (6,000 Watts per circuit), sufficient to electrify 20 to 50 workstations in a single track. This greatly reduces the number of home runs and zones versus generic power distribution systems. With the 707 Series, one or two phases can be designated as variable circuits to de-energize non-essential equipment for Title 24 compliance.

The more economical two-phase 717 Series Snake Bus provides two circuits for up to 12 Kilowatts of power (also 6,000 Watts per circuit), with one phase being capable of communicating with a BMS to de-energize outlets for compliance purposes. With more and more systems using energy efficient LED lighting and low voltage/POE technologies, the 717 Series provides sufficient power to electrify smaller spaces without overspending for unused capacity.

Snake Bus: Bringing innovation to power distribution

Snake Bus is unlike anything else on the market. Certainly, there are other under floor power distribution systems, like those that use flexible conduit and power distribution boxes to electrify zones of workstations in a hub and spoke fashion. But really that’s just another version of pipe and wire under a raised access floor. Here are three reasons why Snake Bus is the best:

- Bus Bar Technology. Bus bars use a single continuous strip of copper to carry current for each circuit rather than multiple strands of copper wire. It consumes approximately 30% less copper than cables running an equal distance, cutting material costs, and reducing the overall carbon footprint. Bus bar technology also has a lower resistance rate than cables, so it experiences less voltage drops and thereby consumes less electricity to power an equal number of devices.

- Pre-manufactured Modularity. Every component and accessory of the Snake Bus system is designed to securely attach with modular connections that snap into place in seconds. There is no time spent stripping and terminating individual wires, no waste, no mistakes, nothing to fabricate on site, and all connections are inherently grounded. Snake Bus tracks, Snake Whips, and enclosures are installed, moved, and reused infinitely, minimizing labor costs at all times.

Electrical Isolation. Circuit breakers are located in each user interface unit at the point of device connection, not back at the power closet to provide the over-current protection. Each pair of duplex outlets is individually controlled by its own breaker installed inside the enclosure, limiting failures to that outlet pair. So, for example, when someone spills coffee on their keyboard, only the breaker for their PC is tripped. There is no daisy chain of power failures that can bring an entire department to a standstill. Snake Bus maintains employee safety while surrounding workstations and equipment are isolated from and unaffected by the event. Extremely versatile, Snake Bus can be configured to control power at the point of distribution rather than the point of need, If desired. Read more about the value of electrical isolation in this article.

Electrical Isolation. Circuit breakers are located in each user interface unit at the point of device connection, not back at the power closet to provide the over-current protection. Each pair of duplex outlets is individually controlled by its own breaker installed inside the enclosure, limiting failures to that outlet pair. So, for example, when someone spills coffee on their keyboard, only the breaker for their PC is tripped. There is no daisy chain of power failures that can bring an entire department to a standstill. Snake Bus maintains employee safety while surrounding workstations and equipment are isolated from and unaffected by the event. Extremely versatile, Snake Bus can be configured to control power at the point of distribution rather than the point of need, If desired. Read more about the value of electrical isolation in this article.

Download our white paper, California Code of Regulations, Title 24 Compliance: Building a Smarter Building is Easy with Snake Tray, to learn more about Title 24 and how Snake Bus can help speed construction and reduce costs while meeting building compliance standards.

Related Article:

California Title 24 Building Compliance & Power Distribution

Snake Bus: The BEST Power Distribution System for Under Raised Access Floors

Chapter 5: Power Up the Possibilities with Snake Bus

The Snake Bus power distribution system deployed in conjunction with RAF allows for easy reconfiguration of spaces as the needs of tenants change over time. Panels can be easily lifted and exchanged for enclosures to modify floor layout for air vent locations, access points for power outlets, network connections, lights, and other systems, in effect “future proofing” the space.

For further insights into the advantages of RAF, the impact of compliance regulations like Title 24 on the construction industry, and the applications for and benefits of using the Snake Bus under floor power distribution system, we encourage you to explore the linked articles and white papers referenced in this article and visit us at www.snaketray.com.

Some things are just made to go together. When you make the decision to go with raised access flooring in your next project, you need to go with Snake Bus for under floor power distribution. Our team of engineers is standing by to map out your custom solution. Contact us to request a consultation.

ABOUT SNAKE TRAY®

Snake Tray has been innovating cable trays, cable management systems, and power distribution solutions since 1996. Our goal is to provide customers with cost-effective solutions that help reduce the total cost of construction. All Snake Tray products are manufactured in the USA and are stocked throughout the country to guarantee delivery without delay to our customers. Our 24-hour technical support gives customers the opportunity to speak with us at any time to discuss their project needs. We welcome the opportunity to help design innovative solutions that help your projects install faster.