Wiring commercial spaces for power is perhaps one of the costliest and labor-intensive aspects of any construction project. Pulling copper through mounted conduit and stub-ups requires expensive skilled labor and is time consuming.

The terminations are at fixed positions, making moves, adds, and changes difficult. The traditional pipe and wire method consumes more copper, requires connection boxes, outlets, and circuit breakers on every line, and makes it complicated to support energy conservation mandates.

There must be a better way to economically electrify large spaces…there is: Raised Access Flooring (RAF) plus the Snake Tray Snake Bus Power Distribution System.

Change Your Perception of Raised Access Floors (RAF)

Think about raised access floors (RAF) and what comes to mind for most of us are ventilated steel plates to cool computers in data centers. While still true, there has been a renaissance in RAF due to several cost and environmental factors.

Think about raised access floors (RAF) and what comes to mind for most of us are ventilated steel plates to cool computers in data centers. While still true, there has been a renaissance in RAF due to several cost and environmental factors.

Today’s raised access floor panels are available in a multitude of colors and finishes to integrate with any design concept. Many are made using sustainable materials for a green design and LEED certification, bringing RAF out of the data center and into the workspace and trafficked areas.

In addition to creating a concealed yet easily accessible space for power distribution while eliminating the issues associated with traditional pipe and wire, RAF offers these advantages:

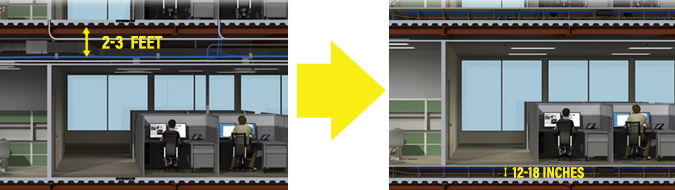

- Greater material efficiency. Raised access flooring lowers typical slab-to-slab height by one to two feet per floor, drastically reducing core and shell material needs while maintaining optimal ceiling height. By running environmental and electrical systems under the floor, only interior lighting, audio, and fire suppression systems require overhead installation. Raised access flooring allows builders to compress building height without sacrificing usable square footage, or they can build more floors to increase occupiable space in the same vertical envelope. In addition to saving space, eliminating HVAC ductwork in favor of low pressure forced air greatly lowers material and labor costs and does away with the need and expense of a dropped ceiling.

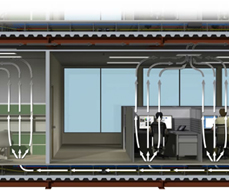

Improves indoor air quality. Pushing forced air up from under the floor improves circulation by minimizing mixing zones. A stratified air system with overhead exhaust/filtration removes pollutants like cigarette smoke, particulates, air-borne germs, and other contaminants for a healthier environment, reducing absenteeism. Employees can control air flow in personal spaces with adjustable air vents for improved comfort

Improves indoor air quality. Pushing forced air up from under the floor improves circulation by minimizing mixing zones. A stratified air system with overhead exhaust/filtration removes pollutants like cigarette smoke, particulates, air-borne germs, and other contaminants for a healthier environment, reducing absenteeism. Employees can control air flow in personal spaces with adjustable air vents for improved comfort Supports layout flexibility. Modular grid design makes it easy to accommodate adds, moves, and changes to room layout to make space for new equipment or workspaces. Easily and quickly reconfigure retail and office spaces for new tenants, and bring power to exhibits, museums, and temporary displays without exposing infrastructure.

Supports layout flexibility. Modular grid design makes it easy to accommodate adds, moves, and changes to room layout to make space for new equipment or workspaces. Easily and quickly reconfigure retail and office spaces for new tenants, and bring power to exhibits, museums, and temporary displays without exposing infrastructure. Enhances daylight Increase window size and volumes to bring in more natural light. Eliminate obstructions from conduit ascending exterior walls in risers and enjoy a more open floor plan with greater energy efficiency. Brighter environments have a positive impact on health, productivity, and attitude of those in the building. Glass is also less expensive than curtain wall building materials, reducing costs.

Enhances daylight Increase window size and volumes to bring in more natural light. Eliminate obstructions from conduit ascending exterior walls in risers and enjoy a more open floor plan with greater energy efficiency. Brighter environments have a positive impact on health, productivity, and attitude of those in the building. Glass is also less expensive than curtain wall building materials, reducing costs.

As a result of these advantages, we are seeing raised access flooring used in more commercial and professional offices as well as call centers, trading floors, museums, art galleries, libraries, casinos, command centers, and similar spaces where there is demand for high density yet flexible power and data distribution.

Environmental and flooring images courtesy of Tate Access Floors, Inc.

Once the case for RAF is made, there’s only one choice when it comes to under floor power distribution: Snake Tray’s Snake Bus.

Snake Bus Under Floor Power Distribution System

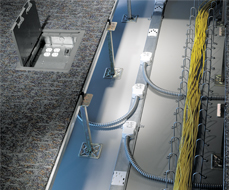

Snake Tray’s prefabricated Snake Bus power distribution system is the fastest, easiest, and most cost-effective way to wire a commercial space for flexible power distribution underneath raised access floors.

It brings efficiencies and predictability to power distribution for spaces from 1,000 to 1,000,000 square feet. Snake Bus is compatible with all post and panel raised floor systems, as well as low profile access floors and will not interfere with under floor air circulation.

The only one of its kind, the modular Snake Bus system uses bus bar technology instead of copper wire and conduit to provide up to 50 Amp, three-phase, 208V service for 18KW of power wherever it is needed in one easy-to-install track – that’s three times the power of conventional lines. More energy efficient than traditional wiring, Snake Bus uses 30% less copper and experiences less voltage drop over long runs, further reducing energy consumption.

The only one of its kind, the modular Snake Bus system uses bus bar technology instead of copper wire and conduit to provide up to 50 Amp, three-phase, 208V service for 18KW of power wherever it is needed in one easy-to-install track – that’s three times the power of conventional lines. More energy efficient than traditional wiring, Snake Bus uses 30% less copper and experiences less voltage drop over long runs, further reducing energy consumption.

Snake Bus tracks are available in 4-foot and 8-foot segments that join in seconds, streamlining installation. Snake Bus tracks are flexible, reusable, and IP-addressable.

Multiple phases built into each track allow for one or two circuits to be designated as a variable power circuit to support energy conservation mechanisms built into today’s smart buildings.

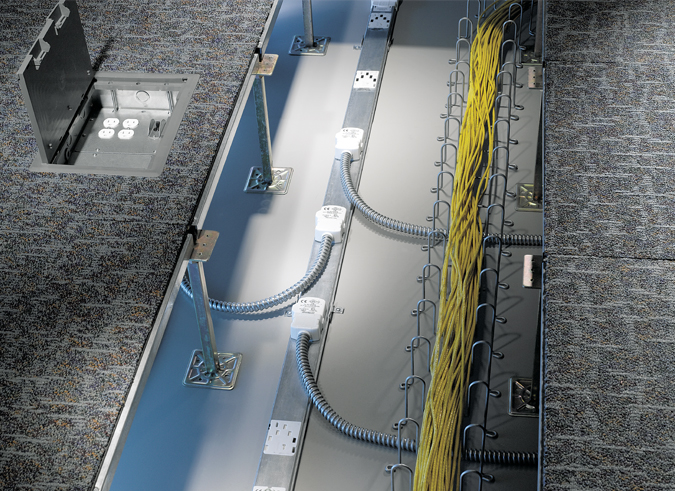

Modular tap offs deliver power to individual offices and workstations by snapping into receptacles positioned every 12 inches along the track for precise placement as needed.

The tap offs are attached to pre-manufactured enclosures such as a recessed floor box or under desk power module to bring power to the surface and these can also be moved and reused as needed. Snake Bus installs in less time with less labor and zero waste.

Its low profile and flexible interlinks allow for easy routing around any obstacle, resulting in an overall 30% reduction in material and labor costs over alternative and traditional hard-wiring methods.

What Makes Snake Bus the Best?

Certainly, there are other under floor power distribution systems, like those that use flexible conduit and power distribution boxes to electrify workstations in a hub and spoke fashion.

Certainly, there are other under floor power distribution systems, like those that use flexible conduit and power distribution boxes to electrify workstations in a hub and spoke fashion.

Each power distribution box functions as a zone with all floor boxes in the zone connected to each other. Let’s compare a generic under floor power distribution system like the one pictured here to Snake Bus.

In the power distribution box scenario, there is flexibility to run power exactly where needed, however each zone has a fixed number of ports and is typically a 20-amp circuit.

In the power distribution box scenario, there is flexibility to run power exactly where needed, however each zone has a fixed number of ports and is typically a 20-amp circuit.

That means a lot of zones to power a large space. Each distribution box requires multiple home runs back to the power closet, and it is at that point where a circuit breaker is installed. For every zone. On every floor. The end result is still a giant web of conduit under the floor.

Now let’s say one of those zones is a row of workstations at a trading desk or call center and someone in that zone spills coffee on their PC. That trips the breaker for the entire zone, bringing trading activity or customer service to a screeching halt for everyone connected in that daisy chain.

Should a gambler spill a drink on a slot machine plug, an entire bank of machines on the same zone can go dark. These are unacceptable outcomes in time-sensitive environments.

Snake Bus serves as a linear sub-panel running directly below the equipment it is powering, providing individual circuits to each device. Snake Bus delivers 18,000 watts of power, sufficient to electrify 20 to 50 workstations in a single track, greatly reducing the number of home runs and zones versus generic power distribution systems.

Snake Bus serves as a linear sub-panel running directly below the equipment it is powering, providing individual circuits to each device. Snake Bus delivers 18,000 watts of power, sufficient to electrify 20 to 50 workstations in a single track, greatly reducing the number of home runs and zones versus generic power distribution systems.

Its multi-phase design makes it easy to tie Snake Bus into building management systems and comply with energy conservation mandates like California Title 24.

Its multi-phase design makes it easy to tie Snake Bus into building management systems and comply with energy conservation mandates like California Title 24.

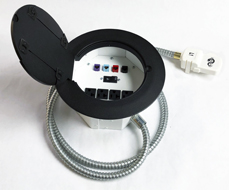

But what really sets Snake Bus apart is that the circuit breakers are located at the point of device connection, not back at the power closet. Each floor box is essentially its own circuit. Each pair of duplex outlets is individually controlled by its own breaker installed inside the floor box – there is no daisy chain of power failures with Snake Bus.

There are fewer parts to purchase and install since all Snake Tray floor boxes are equipped with circuit breakers as standard equipment, which also saves a lot of space back at the power closet by eliminating a breaker for each circuit. In fact, Snake Bus reduces the number of electrical panels per floor by moving breaker positions out of the electrical closet for even greater savings.

So, when someone spills coffee on their keyboard or slot machine, only the breaker for that device is tripped, maintaining employee safety while surrounding workstations and equipment are isolated and unaffected by the event.

Snake Tray offers a number of specialty floor boxes designed to virtually disappear into the RAF. Some have recessed lids that accept the matching floor covering material, some are round for easy use with RAF panels with circular air diffuser openings, others are desk-mounted modules.

Snake Tray offers a number of specialty floor boxes designed to virtually disappear into the RAF. Some have recessed lids that accept the matching floor covering material, some are round for easy use with RAF panels with circular air diffuser openings, others are desk-mounted modules.

All can be customized to meet unique electrical and port configurations. There are also enclosures that offer separate compartments for power, voice, data connections in one – but that’s a topic for another article: adding underfloor cable management to bring connectivity and power to the point of need.

Power Up the Possibilities with Snake Bus

Some things are just made to go together. When you make the decision to go with raised access flooring in your next project, you need to go with Snake Bus for underfloor power distribution. Our team of engineers is standing by to map out your custom solution. Contact us to get started!