Over the years Snake Tray has solved many problems for customers in the process of building, retrofitting, or expanding commercial structures. Engineers, architects and contractors come to us with unique challenges, and together with our engineers, we design and build specialized cable conveyance, enclosures and power distribution systems with minimal labor and material costs. Our ability to innovate, combined with our nimble in-house manufacturing capabilities and flat management style, has earned Snake Tray a reputation as the go-to vendor for customized solutions, quickly solving problems larger companies cannot address.

For example, the Mega Snake® is a simple reimagining of the generic wire basket cable tray whose design had not changed in 50 years. Just a few innovations like dual rails for a built-in suspension system, thicker gauge wire for added strength, and premanufactured fittings for turns and crosses created an entire product line that revolutionized the industry. It’s not that our products do anything different conceptually from competitors—get data cables and power from Point A to Point B—it’s that we do it with far fewer pieces and a huge reduction in labor for great savings.

Today, many of our best selling products are the result of innovations made to solve unique customer problems that proved so effective they went from one-off, niche solutions to catalog mainstays. That’s how Snake Tray grew from a niche player to a mainstay in the data and power distribution market, and why we’ll never lose our focus on innovation. When a customer asks us, Can you build that?, our answer is always Yes! Here are a few examples of how Snake Tray has built a better mousetrap:

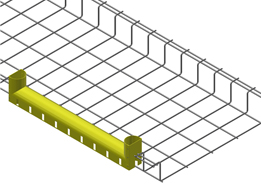

- Side Mount Cable Dropout. Engineers at a hyperscale data center needed to waterfall a tremendous amount of cable into expanded racks of servers below. A smooth surface was needed for a 90

degree bend to ensure cables would not have any potential pinch points or kinks. The issue was that Snake Tray did not provide the original basket tray, and the manufacturer did not offer any accessories nor a solution, except to recommend to cut and grind the trays where dropouts were needed. No problem. In a matter of hours, Snake Tray engineers modified a cable dropout originally designed for our Mega Snake system to be able to work with any generic wire basket tray. It can support high capacity cable waterfalls without any field fabrication or compromising the cable tray itself. The Rail Mount Cable Dropout for Mega Snake is one of the newest members of the Snake Tray catalog, and is available to any customer requiring dropouts on generic wire basket trays.

degree bend to ensure cables would not have any potential pinch points or kinks. The issue was that Snake Tray did not provide the original basket tray, and the manufacturer did not offer any accessories nor a solution, except to recommend to cut and grind the trays where dropouts were needed. No problem. In a matter of hours, Snake Tray engineers modified a cable dropout originally designed for our Mega Snake system to be able to work with any generic wire basket tray. It can support high capacity cable waterfalls without any field fabrication or compromising the cable tray itself. The Rail Mount Cable Dropout for Mega Snake is one of the newest members of the Snake Tray catalog, and is available to any customer requiring dropouts on generic wire basket trays. - Snake Tray Solar Max. As the size of solar panel arrays grew, so did the size and number of cables carrying wattage to inverters.

A major electrical contractor wanted to speed construction of a solar plant for a utility. It was time consuming to trench, and profits were evaporating as thicker, more expensive cables were required to offset the derate of buried lines. Within days, Snake Tray engineers had designed an above-ground conveyance system using suspended insulated cable separators to handle the wattage produced by large solar arrays without suffering derate, and the Solar Max system was born. Today, Solar Max is the leading free-air installation method for solar arrays across the country with an entire family of accessories.

A major electrical contractor wanted to speed construction of a solar plant for a utility. It was time consuming to trench, and profits were evaporating as thicker, more expensive cables were required to offset the derate of buried lines. Within days, Snake Tray engineers had designed an above-ground conveyance system using suspended insulated cable separators to handle the wattage produced by large solar arrays without suffering derate, and the Solar Max system was born. Today, Solar Max is the leading free-air installation method for solar arrays across the country with an entire family of accessories. - Snake Nut™ Threaded Rod Fastener. When one of our customers asked for an easy way to get a fastener up a threaded ro

d to suspend a cable run, we invented the Snake Nut. This innovative open-ended fastener eliminates the labor intensive need to hand-spin hex nuts up a threaded rod. Simply place the Snake Nut at the desired position on the threaded rod and tighten with a setscrew. Once locked into place, Snake Nut has been tested to hold up to 6,800 pounds. It’s also an easy way to add a second layer of basket tray to an existing hanging run.

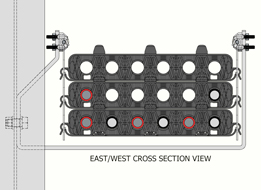

d to suspend a cable run, we invented the Snake Nut. This innovative open-ended fastener eliminates the labor intensive need to hand-spin hex nuts up a threaded rod. Simply place the Snake Nut at the desired position on the threaded rod and tighten with a setscrew. Once locked into place, Snake Nut has been tested to hold up to 6,800 pounds. It’s also an easy way to add a second layer of basket tray to an existing hanging run. - Passive Optical Network (PON) Ceiling Enclosures. With their 100-year-old New England campus upgrading to fiber optic, a major insurance carrier needed a way to get modernized technology into every workspace. But their telecommunications rooms were maxed out with no place for expansion. Snake Tray designed an enclosure to fit into standard 2′ x 2′ or 2′ x 4′ drop ceilings. The PON module installs flush to the ceiling with a hinged drop-down door that houses all the equipment—Optical Network Transceivers (ONT) to convert fiber optic to copper signals, switches, power supplies, cooling fans, and access points—to connect all devices at the point of need. It is basically a remote mini telecommunications closet placed in the ceiling of every workspace. A single fiber connection links the PON back to

the MDF. Today, Snake Tray offers an entire family of wall, raised floor, and ceiling enclosures in multiple shapes and sizes to enable schools, government agencies, and institutions housed in older buildings to take advantage of the latest networking technologies.

the MDF. Today, Snake Tray offers an entire family of wall, raised floor, and ceiling enclosures in multiple shapes and sizes to enable schools, government agencies, and institutions housed in older buildings to take advantage of the latest networking technologies.

Do you have a unique cable conveyance or power distribution challenge that others have been unable to solve? Contact Snake Tray and let us innovate with you. We have the expertise and flexibility to transform your unique needs into repeatable solutions.

Snake Tray has revolutionized the data and power distribution market with cable management, power distribution systems and enclosures all designed to install quickly, reduce labor and material costs, and significantly drive down the total cost of construction. If you would like to learn more, visit us at snaketray.com. Our engineers and sales teams stand ready to help execute your next cabling project with maximum efficiency and profitability.