Sustainability and compliance are two hot topics in the construction industry today. Every project is designed with an eye on its environmental impact while meeting various building codes and standards for safety and liability. This article discusses how Snake Tray cable management and power distribution systems support those efforts.

Sustainable is Maintainable and Justifiable

There’s a myth out there that sustainable construction practices inflate costs; that shrinking the carbon footprint of a building comes at a price. But earning Leadership in Energy and Environmental Design (LEED) points using eco-friendly materials and construction techniques to improve energy efficiency, lower emissions and reduce waste doesn’t have to add to your bottom line.

Material reuse. Snake Tray hand-bendable and wire basket cable trays can be redeployed as building use changes over time. The drop-in Snake Canyon® cable management system creates movable cable pathways beneath raised access floors. The modular Snake Bus® under floor power distribution system can be infinitely expanded or relocated as needed.

Material reuse. Snake Tray hand-bendable and wire basket cable trays can be redeployed as building use changes over time. The drop-in Snake Canyon® cable management system creates movable cable pathways beneath raised access floors. The modular Snake Bus® under floor power distribution system can be infinitely expanded or relocated as needed. Recycled materials. Snake Tray cable trays are made from 100% recycled steel, minimizing virgin raw materials used in your next project. The Snake Bus power distribution system is made from 75% recycled materials, and at end of life 99% of the system can be reclaimed.

Recycled materials. Snake Tray cable trays are made from 100% recycled steel, minimizing virgin raw materials used in your next project. The Snake Bus power distribution system is made from 75% recycled materials, and at end of life 99% of the system can be reclaimed. Elimination of construction waste. Pre-manufactured Mega Snake® basket tray turns, Tee’s, and intersections, and our hand-bendable trays eliminate labor-intensive on-site fabrication and the resulting waste of cutting straight sections into customized fittings. The Snake Bus system removes the need for conduit and wire, saving truckloads of leftover pipe and cable scraps from the landfill. Just snap Snake Bus tracks sections together.

Elimination of construction waste. Pre-manufactured Mega Snake® basket tray turns, Tee’s, and intersections, and our hand-bendable trays eliminate labor-intensive on-site fabrication and the resulting waste of cutting straight sections into customized fittings. The Snake Bus system removes the need for conduit and wire, saving truckloads of leftover pipe and cable scraps from the landfill. Just snap Snake Bus tracks sections together. Improved energy efficiency. Snake Bus uses bus bar technology that is more energy efficient than copper wire, and in fact uses 30% less conductive material to save natural resources and cost. Further, Snake Bus experiences less voltage drop over long runs versus traditional copper wire, reducing overall energy consumption.

Improved energy efficiency. Snake Bus uses bus bar technology that is more energy efficient than copper wire, and in fact uses 30% less conductive material to save natural resources and cost. Further, Snake Bus experiences less voltage drop over long runs versus traditional copper wire, reducing overall energy consumption. Reduced Building Height and Construction Materials. Snake Tray products can lower building height by up to 10% per story without impacting usable square footage, reducing the total volume of construction materials. When used in conjunction with raised access floors and under-floor forced air HVAC, all critical power, data and communication systems can be installed within that space, eliminating the need for suspended ceilings and miles of ductwork.

Reduced Building Height and Construction Materials. Snake Tray products can lower building height by up to 10% per story without impacting usable square footage, reducing the total volume of construction materials. When used in conjunction with raised access floors and under-floor forced air HVAC, all critical power, data and communication systems can be installed within that space, eliminating the need for suspended ceilings and miles of ductwork. Streamlined packaging and shipping. Snake Tray products nest together for compact shipping. We use fewer packaging materials which also reduces waste, fuel consumption, and emissions during transit to the job site. Load up to six skids of Mega Snake basket trays in the space of one skid of competitors’ trays and save up to 85% in freight costs.

Streamlined packaging and shipping. Snake Tray products nest together for compact shipping. We use fewer packaging materials which also reduces waste, fuel consumption, and emissions during transit to the job site. Load up to six skids of Mega Snake basket trays in the space of one skid of competitors’ trays and save up to 85% in freight costs.

Compliance Requires Obedience and Deference

Whereas sustainability is often optional, compliance is not. Builders may be rewarded or penalized for how they implement LEED, but outside of some government projects, there is no legal requirement mandating sustainability. Not so for compliance.

In the construction industry there are all kinds of building codes for safety, wood framing, windows/insulation, hazardous materials, HVAC systems, fire, emergency exits, handicap accessibility, electrical systems, elevators, and yes, even cable trays and loading capacities. These standards are created and enforced by authorities at the local, state, and federal level. You’ll hear acronyms like OSHA, IBC, NEC, UL, ANSI, CSI. Builders not meeting code compliance standards are subject to fines, licensing, and legal outcomes much more severe than losing a few LEED points, especially if injuries or deaths result from non-compliance.

Snake Tray Rewrites Cable Tray Compliance Standards

However, many of these building codes are outdated, written decades before the advent of smart buildings, data networks, stronger yet lighter materials, and new construction practices.

In many instances the standards were authored in partnership with advocates or manufacturers of a specific solution, injecting bias into the codes to favor their specs or materials come bid time. While we cannot speak to all building codes, we do know that the standards created by the Construction Specifications Institute (CSI) for legacy cable trays were influenced by manufacturers using outdated mechanical principles and specifications that disqualified many next-generation competitive products from consideration (sometimes on purpose), such as those by Snake Tray.

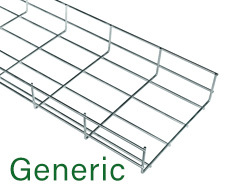

The CSI is a United States national association of more than 6,000 construction industry professionals who are experts in building construction and the materials used therein. The CSI had decreed that all wire basket trays must be constructed from steel wire in a 2″ x 4″ grid pattern with a lateral spine (which ended up prohibiting hand-bendable trays).

This became excessive, as much of the cable plant in today’s buildings evolved into lightweight low voltage data (PoE), communications, and fiber optic lines. Traditional basket trays with a 2″ x 4″ grid were overkill and unnecessarily inflated costs.

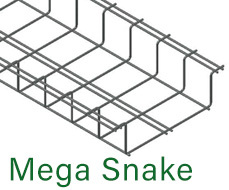

Generic wire basket trays are typically made with 0.120″ to 0.187″ gauge (3 to 4.75 mm) stainless steel rods welded into a 2″ x 4″ grid. Most have a maximum weight rating of about 75 lbs. per linear foot when the tray is supported every five feet.

Generic wire basket trays are typically made with 0.120″ to 0.187″ gauge (3 to 4.75 mm) stainless steel rods welded into a 2″ x 4″ grid. Most have a maximum weight rating of about 75 lbs. per linear foot when the tray is supported every five feet.

Snake Tray had better solutions. Manufactured with 0.250″ gauge (6.35 mm) steel rods, our Mega Snake wire basket tray doubled the strength of generic trays and held up to 150 lbs. of cables per linear foot when mounted every five feet at double the grid spacing of 4″ x 4″ — all at a fraction of generic tray weight, materials, and cost.

Snake Tray had better solutions. Manufactured with 0.250″ gauge (6.35 mm) steel rods, our Mega Snake wire basket tray doubled the strength of generic trays and held up to 150 lbs. of cables per linear foot when mounted every five feet at double the grid spacing of 4″ x 4″ — all at a fraction of generic tray weight, materials, and cost.

Snake Trays hand-bendable trays also outperformed the competition. They were stronger yet flexible, did not require a lateral spine, and offered built-in mounting rings at 4″ intervals. Yet according to CSI, like the Mega Snake, they weren’t up to code.

Unacceptable! Snake Tray worked with CSI to modernize its codes for cable trays. Through education and scientific testing, we were able to prove that Snake Tray products outperformed legacy products using less/lightweight materials. As a result, we got CSI to change from a rigid mechanical 2″ x 4″ grid spec to performance-based standards based on weight, capacity, and strength, opening the door for Snake Tray solutions to be considered for every cabling project.

Take Charge of Compliance

When it comes to cable management, Snake Tray is a leader in helping set industry standards for sustainability and compliance. In cases where technological innovations have surpassed the codes written to govern its use, Snake Tray is there to ensure standards change with the times and keep you in compliance with building codes by using the most modern solutions.

Have questions about how you can ensure your next project meets industry mandates for sustainability and compliance? Talk to one of our experts. We’ll make sure you’re up to speed.