If there’s one thing that sets Snake Tray apart from every other cable tray manufacturer, it is our capacity to build innovative, customized solutions for clients’ unique problems.

Whereas most other cable tray manufacturers offer only stock products or require excessive lead times and upcharges to fabricate customized solutions, Snake Tray embraces these challenges. In fact, our greatest strength is the ability to create one-of-a-kind cable management products, enclosures, and power distribution systems alongside Snake Tray’s extensive family of standard products.

We liken ourselves to an engineering firm with a manufacturing arm attached – possessing the agility, know-how, and skills to quickly go from conception to production. As testament, here are several examples of original solutions made possible by Snake Tray’s willingness to go the extra mile and turn ideas into reality.

Innovative Solutions for Unique Environments

- George Lucas Museum of Narrative Art in Los Angeles.

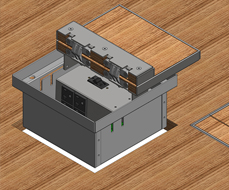

Snake Tray designed a concealed floor box for use over a raised access floor to bring power and data terminals to a massive gallery space that would be in constant flux. The floor boxes are designed to be virtually imperceptible to the naked eye when not in use by exactly matching the elegant woodgrain floor finish and sitting perfectly flush with the surface to avoid a tripping hazard. When the space needs to be reconfigured for a new exhibit or event, a suction cup is used to lift and slide the hinged lid to expose the ports and receptables below. A display stand, table or furnishing is then positioned over the enclosure for concealed power and connectivity. Read the full case study here.

Snake Tray designed a concealed floor box for use over a raised access floor to bring power and data terminals to a massive gallery space that would be in constant flux. The floor boxes are designed to be virtually imperceptible to the naked eye when not in use by exactly matching the elegant woodgrain floor finish and sitting perfectly flush with the surface to avoid a tripping hazard. When the space needs to be reconfigured for a new exhibit or event, a suction cup is used to lift and slide the hinged lid to expose the ports and receptables below. A display stand, table or furnishing is then positioned over the enclosure for concealed power and connectivity. Read the full case study here. - 9/11 Memorial & Museum in New York City.

After completing a series of traditional cable runs for the 9/11 Memorial, the Committee asked Snake Tray to design a special arched cable conveyance for the 9/11 Museum, located seven stories below the Memorial. The Museum’s core exhibitions are housed in a large, elliptical-shaped hall with a series of automated doors along a 160’ long curved entryway. Requiring more capacity/weight than a hand bendable tray could support, Snake Tray designed a rigid, high-volume cable pathway with specialized mounting hardware that precisely followed the sweeping arc of the wall. The cables that securely carry the power and sensor cables that allow the hall’s doors to open and close.

After completing a series of traditional cable runs for the 9/11 Memorial, the Committee asked Snake Tray to design a special arched cable conveyance for the 9/11 Museum, located seven stories below the Memorial. The Museum’s core exhibitions are housed in a large, elliptical-shaped hall with a series of automated doors along a 160’ long curved entryway. Requiring more capacity/weight than a hand bendable tray could support, Snake Tray designed a rigid, high-volume cable pathway with specialized mounting hardware that precisely followed the sweeping arc of the wall. The cables that securely carry the power and sensor cables that allow the hall’s doors to open and close. - Museum of Modern Art (MOMA) in New York City.

Adjacent to the MOMA is the 77-story MOMA Tower, one of the tallest skyscrapers in Manhattan. The mixed-use tower houses luxury condominium apartments and expanded gallery space for the Museum. The lower levels were occupied even as the upper floors were being finished. In fact, most of the infrastructure was in place, including the apparatus and pipes for the exterior window washing system at the very top. That’s when the electrician called in Snake Tray to design and build customized narrow cable pathways to bring power and connectivity to the highest and most space-constricted points of the tower – out of sequence. Snake Tray designed modified cable tray segments that not only had to navigate around previously installed systems, but also fit into residential elevators and then carried up a series of ladders to the apex of the building to wire the window washing system in a tightly confined space.

Adjacent to the MOMA is the 77-story MOMA Tower, one of the tallest skyscrapers in Manhattan. The mixed-use tower houses luxury condominium apartments and expanded gallery space for the Museum. The lower levels were occupied even as the upper floors were being finished. In fact, most of the infrastructure was in place, including the apparatus and pipes for the exterior window washing system at the very top. That’s when the electrician called in Snake Tray to design and build customized narrow cable pathways to bring power and connectivity to the highest and most space-constricted points of the tower – out of sequence. Snake Tray designed modified cable tray segments that not only had to navigate around previously installed systems, but also fit into residential elevators and then carried up a series of ladders to the apex of the building to wire the window washing system in a tightly confined space. - Congressional Buildings in Washington, D.C.

Most government buildings in the Capitol were built long before the advent of modern communication technologies and have no planned spaces or cable pathways for today’s IT infrastructure. To bring the US House of Representatives and various Department of State buildings up to speed, Snake Tray designed and built customized recessed wall enclosures to house the terminal data ports and network switches that now bring connectivity and digital services to federal offices.

Most government buildings in the Capitol were built long before the advent of modern communication technologies and have no planned spaces or cable pathways for today’s IT infrastructure. To bring the US House of Representatives and various Department of State buildings up to speed, Snake Tray designed and built customized recessed wall enclosures to house the terminal data ports and network switches that now bring connectivity and digital services to federal offices. - US Bank Data Center in Minnesota.

For this project the IT team at US Bank commissioned Snake Tray to build customized server cabinets independent of the data and power cables running to each cage in the bank’s data center. Taking a bottom-up approach, we designed modular rolling cabinet frames for use over a raised access floor. The cabinets easily attach/detach from all connective infrastructure so that engineers can quickly swap server racks in and out for upgrades and repairs with minimal disruption.

For this project the IT team at US Bank commissioned Snake Tray to build customized server cabinets independent of the data and power cables running to each cage in the bank’s data center. Taking a bottom-up approach, we designed modular rolling cabinet frames for use over a raised access floor. The cabinets easily attach/detach from all connective infrastructure so that engineers can quickly swap server racks in and out for upgrades and repairs with minimal disruption. - Command & Control Center for Camp Slayer, Iraq.

During the 2003 Iraq War, the US Army asked Snake Tray to create a turnkey cable management and power distribution system for a military intel base occupying Saddam Hussain’s former palace in Baghdad. Provided only with raw dimensions (a circular space 120’ in diameter), we fabricated, assembled and tested a customized cable conveyance and power distribution system designed to the exact room size, disassembled it, and shipped it to Iraq for reassembly by Army engineers. As the palace was to be returned to the Iraqi people after the war, our solution had to preserve the architectural integrity of the room, which was adorned in pink marble. Using specialized mounting hardware to minimize installation damage, we provided network connectivity and power pathways to a group of 120 officers coordinating military activities during the war, and later served as headquarters for the Iraq Survey Group until 2005.

During the 2003 Iraq War, the US Army asked Snake Tray to create a turnkey cable management and power distribution system for a military intel base occupying Saddam Hussain’s former palace in Baghdad. Provided only with raw dimensions (a circular space 120’ in diameter), we fabricated, assembled and tested a customized cable conveyance and power distribution system designed to the exact room size, disassembled it, and shipped it to Iraq for reassembly by Army engineers. As the palace was to be returned to the Iraqi people after the war, our solution had to preserve the architectural integrity of the room, which was adorned in pink marble. Using specialized mounting hardware to minimize installation damage, we provided network connectivity and power pathways to a group of 120 officers coordinating military activities during the war, and later served as headquarters for the Iraq Survey Group until 2005. - SUNY Oswego Dormitory Renovation.

When the Dormitory Authority of the State of New York (DASNY) decided to bring modern network technology to SUNY Oswego’s 1960s-era cinderblock college dormitories without tearing the buildings apart, they called Snake Tray. We designed customized cable pathways affixed to the ceiling of each room above the window line. The pathways run the entire length of every floor through holes drilled into interior adjoining walls. After the cables were pulled and drop-offs completed for each dorm, the tray was then fitted with a prefabricated sheet metal valance to protect the cables and network access points within. We provided all the materials to cable six multi-story buildings over the course of a summer break, minimizing impact on student life. Read the full story here.

When the Dormitory Authority of the State of New York (DASNY) decided to bring modern network technology to SUNY Oswego’s 1960s-era cinderblock college dormitories without tearing the buildings apart, they called Snake Tray. We designed customized cable pathways affixed to the ceiling of each room above the window line. The pathways run the entire length of every floor through holes drilled into interior adjoining walls. After the cables were pulled and drop-offs completed for each dorm, the tray was then fitted with a prefabricated sheet metal valance to protect the cables and network access points within. We provided all the materials to cable six multi-story buildings over the course of a summer break, minimizing impact on student life. Read the full story here. - Johns Hopkins University in Baltimore, Maryland.

When building the Laboratory for Computational Sensing and Robotics (LCSR), one of the most advanced robotics research centers in the world, the architects called Snake Tray for the cable management aspects of the project. They needed high-capacity overhead cable pathways for the countless machines and workstations that would occupy the large, open lab floorplan. The architects wanted to achieve a particular look that would integrate aesthetics and function into the space’s modern robotics applications. Snake Tray conceived and designed a heavy-duty cable ladder system that encircled the perimeter of the lab with integrated elements to power and hang jelly jar lighting fixtures. The resulting pathway combine data and power cables with functional lighting infrastructure in a single suspended pathway to make an architectural statement.

When building the Laboratory for Computational Sensing and Robotics (LCSR), one of the most advanced robotics research centers in the world, the architects called Snake Tray for the cable management aspects of the project. They needed high-capacity overhead cable pathways for the countless machines and workstations that would occupy the large, open lab floorplan. The architects wanted to achieve a particular look that would integrate aesthetics and function into the space’s modern robotics applications. Snake Tray conceived and designed a heavy-duty cable ladder system that encircled the perimeter of the lab with integrated elements to power and hang jelly jar lighting fixtures. The resulting pathway combine data and power cables with functional lighting infrastructure in a single suspended pathway to make an architectural statement.

Common Denominators

For each one of this scenarios Snake Tray worked hand-in-hand with the customer to go from initial conversation to drawings, prototypes and into production in a matter of days. Many of these customized solutions would be difficult if not impossible for larger, less agile manufacturers to undertake, and we dare say most would pass on many of the one-off projects we routinely accept.

Whether your needs call for a stock product or customized solution, you can be sure that we are ready to rise to your next challenge knowing that all Snake Tray products…

- Are made using post-consumer recycled steel and reclaimed materials.

- Are manufactured right here in the USA at our Long Island, New York facility.

- Install with zero waste – there’s no cutting, clipping, welding or on-site fabrication.

- Nest together for compact shipping, use fewer packaging materials for reduced freight costs and are easier to handle on the job site.

- Offer highly repeatable installation steps with fewer tools, in less time and no mistakes.

- Are available in a range of sizes, finishes and colors, all UL and NEC approved.

- BABA Compliant

Snake Tray: Your Partner for Innovation

Need a never-before-seen solution to your unique cable management, enclosure, or power distribution conundrum? We love taking on projects others won’t touch. We’re your go-to partner for customized solutions. Let’s innovate together. Contact us today!