Learn why one of the world’s leading authorities on energy and technology believes we will face critical power shortages soon if we don’t act quickly, and how Snake Tray products can be part of the solution.

Learn why one of the world’s leading authorities on energy and technology believes we will face critical power shortages soon if we don’t act quickly, and how Snake Tray products can be part of the solution.

Sustainability and compliance are two hot topics in the construction industry today. Every project is designed with an eye on its environmental impact while meeting various building codes and standards for safety and liability. This article discusses how Snake Tray cable management and power distribution systems support those efforts.

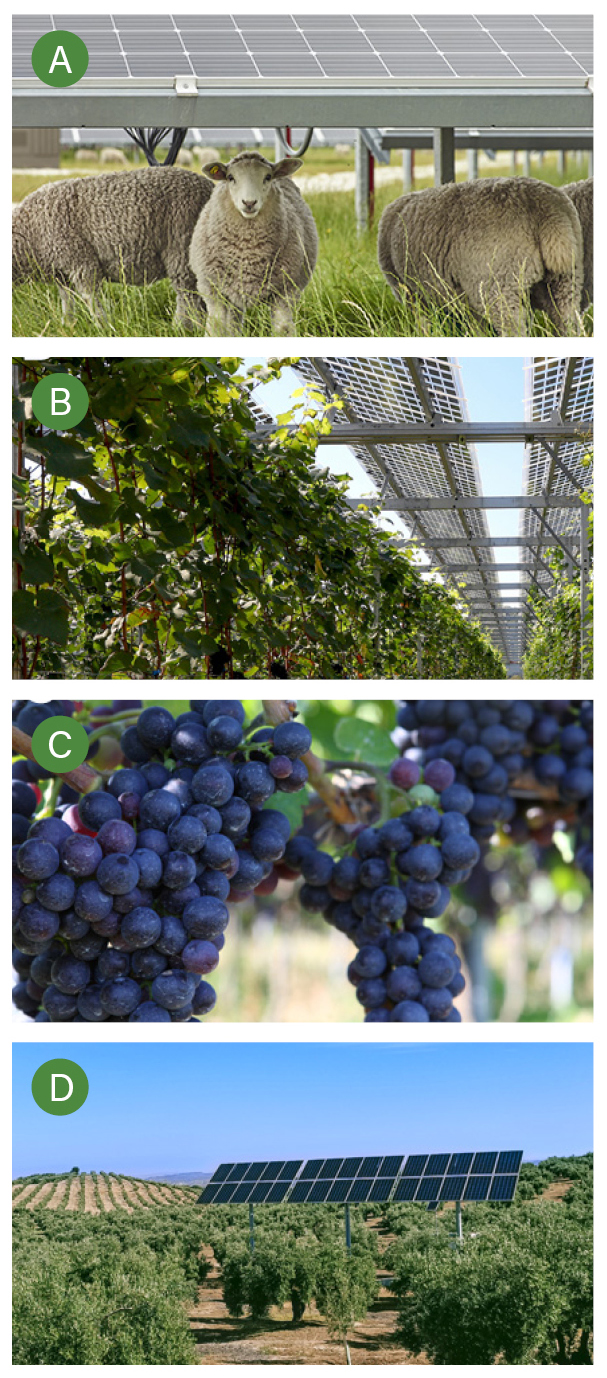

From Texas to New Zealand, flocks of sheep leisurely graze on natural green grasses growing beneath hundreds of rows of solar panels. A

From Texas to New Zealand, flocks of sheep leisurely graze on natural green grasses growing beneath hundreds of rows of solar panels. A

In the Midwest US, researchers have discovered that solar farms can coexist with crops that thrive in partial shade. B

Across the south of France, vineyards are growing grapes for winemaking under the shade and protection of solar panels. C

Spain, famous for its olive oil, integrates solar fields with hedgerow olive tree groves for clean energy generation without disrupting crop production. D

We want to see your next construction project succeed whether you choose Snake Tray as your partner for cable management solutions or not (although we don’t know why you wouldn’t).

From ChatGPT and virtual assistants to fraud detection, medical diagnoses, predictive eCommerce engines and automating countless other tasks, AI is impacting how we see and interact with the world around us.

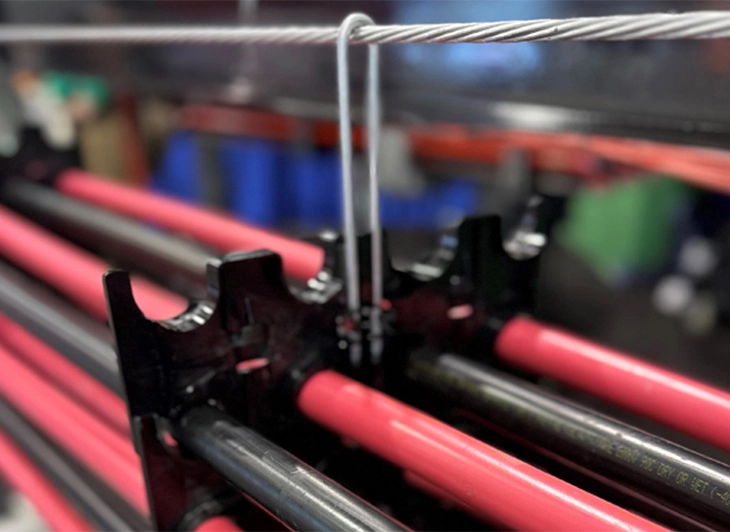

Snake Tray, inventor of the revolutionary cable management system for high ampacity DC cables at utility-grade solar plants, is excited to introduce a new addition to its growing catalog of above ground cable conveyance solutions: the Solar Snake Max ™ – Single Messenger Wire.

We’ve all seen how quickly a hotel can be erected. One day cement mixers arrive on a job site to pour a foundation and cast wall forms on the adjacent ground. Shortly after, cranes are brought in to lift the concrete slabs and support columns into their positions and voila! a new Marriott Courtyard, Best Western, Hampton Inn, or Holiday Inn Express appears in just a few weeks’ time.

Snake Tray has worked with several nationally acclaimed casinos across North America, installing our Snake Bus power distribution system and hand-bendable cable trays beneath the raised access floors (RAF) on which gaming tables and slot machines stand. This article explains why casinos favor RAFs and how Snake Tray solutions are a natural fit.

Some utilities are producing so much renewable solar energy that supply is outpacing demand. They need to store that surplus electricity to power the grid with clean energy after sunset and to complement fossil fuel-based energy production during peak consumption periods or unplanned outages. To make that happen utilities are building battery energy storage systems (BESS) adjacent to the solar panel arrays and inverters that transform megawatts of DC current into usable AC power.

Casino Snake is the modular answer to providing multiple power and data circuits to gaming machines in the casino. This plug-and-play system allows you to add and delete equipment or make moves quickly and easily. The unit is UL listed and approved to connect and disconnect while energized, meaning the circuit breaker does not need to be locked to make changes. As easy as unplugging a lamp, the user can disconnect and move an entire cluster of machines with a minimal amount of disruption to the gaming floor.