Connect two sections of runway end-to-end.

Kit consists of:

• (4) Slice plates

• (2) 3/8″-16 trimmed head bolts

• (2) 3/8″-16 hex nuts

• (2) 3/8″ split lock washers

Connect two sections of runway end-to-end.

Kit consists of:

• (4) Slice plates

• (2) 3/8″-16 trimmed head bolts

• (2) 3/8″-16 hex nuts

• (2) 3/8″ split lock washers

Connect two sections of runway end-to-end.

Kit consists of:

• (4) slice plates

• (2) 3/8″-16 trimmed head bolts

• (2) 3/8″-16 hex nuts

• (2) 3/8″ split lock washers

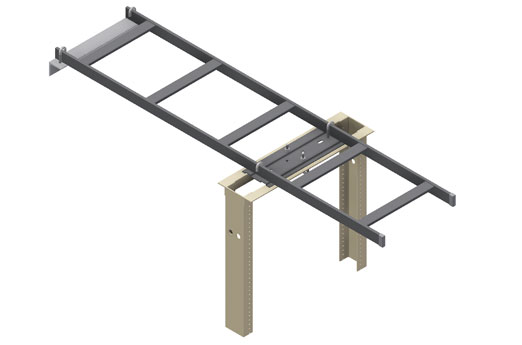

The 5′ (1524 mm) length of this cable runway is designed to meet UPS requirements without additional charges. The 5′ (1524 mm) length of this cable runway is designed to meet UPS requirements without additional charges.

Kit consist of:

• (1) 5′ sections of cable runway

• (1) Wall Bracket

• (1) Rack Bracket

• Also available in 18″ and 24″ widths.

• For 4″ or 6″ Aluminum Cable Tray

• Design load is 4,000#/pair.

• Four bolt attachment.

• Cable Tray attachment hardware is included. Hardware to attach the bracket to the substrate sold separately.

• Recommended for support of vertical pathways.

• Design Load is 1500#/pair Safety factor of 2.5.

• Furnished in pairs.

• Designed for use with either ½” threaded rod. (Order rod separately).

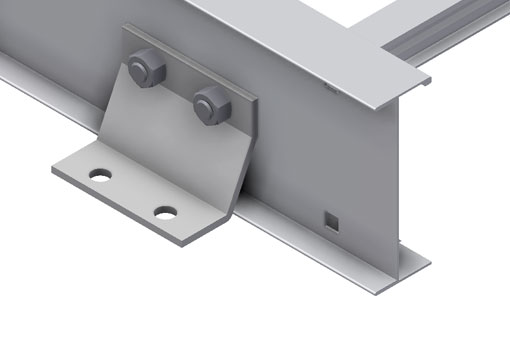

• Wall bracket allows for the cable tray to be attached to a vertical surface.

• Constructed from steel, this bracket will support the tray as well as the load.

• Wall anchors MUST be designed to handle a shear load of the bracket as well as the load with a safety factor of 2.5. Eccentric loading is not to exceed 60% vs. 40% load differential.

• 24″, 30″ and 36″ wall mounted tray support with gusset

• Center Hung Cable Tray Support allows cable to be installed from both sides

• Eliminates costly cable pulling and field cutting of cable tray supports. Labor costs are drastically reduced

• Required hardware and threaded rod material for trapeze assemblies are reduced by 50%

• Designed for use with ½” threaded rod (order rod separately)

• Use with all aluminum and steel cable trays up to 24″ in width

• Load capacity is 700 lbs. per support. Safety factor of 3

• Eccentric loading is not to exceed a 60% vs. 40% load differential

• The maximum recommended unsupported span length is 144″/12 ft. (3.66m)

• Furnished with installation hardware

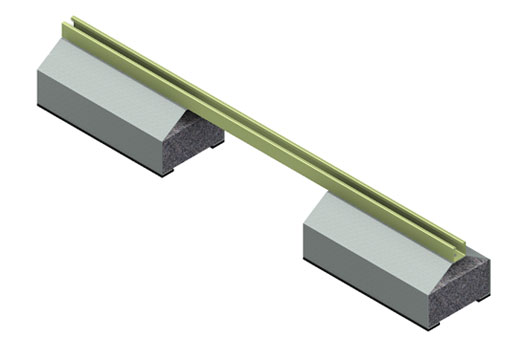

• Designed for use as a rooftop support for cable tray

• Each support has rubberized pads on the underside of each leg to minimize any chaffing of the existing rooftop

• Can be used with any of Snake Tray cable tray clamps and guides

• Ultimate Load Capacity: 1,000 lbs. (uniform load)

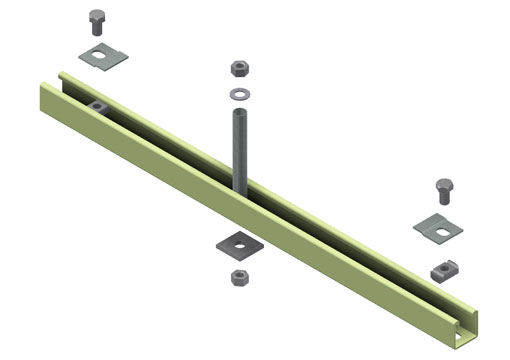

• Provides the necessary components for a single trapeze support in one kit. These kits are available in pre-galvanized steel with zinc plated hardware

• The support bar provides convenient pre-punched slots, eliminating the need for field drilling

• The entire kit is sealed in a plastic bag and boxed with the channel, which is pre-cut to the appropriate length as

shown in the chart

• Designed for use with ½” threaded rod (order rod separately)