Underfloor cable management is essential for modern office environments where connectivity, flexibility, and efficiency are critical. This case study highlights how a leading entertainment company overcame the challenge of dense cabling in limited raised access flooring space by implementing a customized Snake Tray® solution that improved performance, aesthetics, and installation speed.

The Situation

One of the world’s oldest and most venerable entertainment companies is putting the finishing touches on its new headquarters on Manhattan’s Lower West Side. Occupying an entire city block, when completed the building will consolidate multiple business units, various media, news and editorial departments, executive offices and television production studios into one state-of-the-art facility to better foster collaboration and creativity.

Designed with first-class work amenities and a wide-open floor plan, the building is equipped to evolve with changes in technology, business goals, and space requirements. In addition to a full-service café, outdoor terraces, large event spaces, open meeting areas, hundreds of offices and workstations, a theater, reading rooms, wellness and shower facilities, a company store and more, the multi-story complex houses three large production studios where audiences will participate in the live broadcasting and recorded taping of TV shows and streamed events.

This is not the first mega-structure the entertainment giant has built; the company has several campuses, parks and production studios around the world. Nor is this the first time they have worked with Snake Tray. In fact, the relationship goes back some 30 years with Snake Tray providing the cable conveyance for its regional offices and privately-owned data centers that dot the U.S. eastern seaboard.

Now, with the company wanting to take maximum advantage of its new NYC headquarter location, they once again reached out to Snake Tray to provide a customized solution. This time the task was to help design the cable pathways and trays that would run underneath seven floors of raised access flooring to bring low voltage data and telecommunication cables to scores of offices and workstations whose layout would be subject to constant rearrangement.

Each floor occupied 90,000 square feet for a total of over 600,000 square feet of office space that needed to be wired for flexible connectivity. But of course, there’s more to the story.

The Challenge

The architects chose Raised Access Floors (RAF) for floors three, four, five, six, seven, nine and eleven because the alternatives either would have been an unsightly mess of Cat6 cables dropping down to workstations from above or installing fixed data ports that would hinder the very versatility they were trying to achieve.

Six-inch risers were selected to maximize floor height. That meant it was going to be a tight squeeze beneath the RAF. The low profile didn’t leave room for basket trays or the struts and supports some systems need to hang the trays to keep cables off the floor.

Fortunately, only low voltage and line voltage would run under the floor; HVAC, lighting, audio and other smart building systems were to be installed above dropped ceilings. Further, the low voltage pathways were to be independent of the high voltage lines.

The architects had chosen a separate modular hub-and-spoke power distribution system to provide AC current to the workstations and various equipment used in the offices and production studios.

Not only did the cable trays have to be wide yet shallow to accommodate the huge number of data and telecommunication cables, but a key requirement was that cables could not touch the floor. The pathways had to be elevated to allow for 360° airflow around the cables for cooling and to prevent exposure to water and moisture absorption from contact with concrete surfaces.

The low voltage cable pathways needed to navigate around the 90,000 square foot grid pattern of RAF risers on each floor as well as jump over the web of AC power lines that crisscrossed the subfloor. The architects briefly considered using zip ties to bundle subsets of cables and attach them to the RAF pedestals as they peeled off from the central trunk pathways to workstations. However, this would not offer the necessary support over long distances and would make future moves, adds, changes and repairs extremely difficult.

The architects sought a conveyance solution that would easily negotiate around/over random obstacles and provide the necessary cabling flexibility within a very constrained vertical space. Of course, it also had be affordable, reusable and install quickly with minimal labor to meet budget and scheduling demands. Enter Snake Tray.

The Snake Tray Solution

Snake Tray engineers reviewed the third, fourth, fifth, sixth, seventh, nineth and eleventh floor blueprints to help project architects optimize the cable pathways. It quickly became apparent a modified version of the 101 Series Underfloor Snake Tray was the answer.

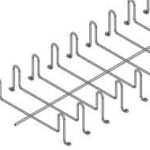

Designed for installation below a raised access floor, the 101 Series Snake Tray is strong yet hand bendable. Constructed from ¼” galvanized or stainless steel rods, it has a single center spine that can be shaped into any horizontal or vertical position and make directional changes without any tools to create fully supported cable pathways around or over any obstruction.

Its self-supporting legs keep cables safely elevated above the floor as mandated, while built-in mounting rings eliminate the need for brackets and braces (for which there was no room). Installers simply mount the tray to the subfloor using concrete anchors at 4-foot to 5-foot intervals to keep the trays in position. The 101 Series Snake Tray installs faster and requires less manpower than any other option, saving labor costs. All other competitive cable trays require mounting accessories. The patented 101 Series Snake Tray is the only one-piece solution on the market.

Its self-supporting legs keep cables safely elevated above the floor as mandated, while built-in mounting rings eliminate the need for brackets and braces (for which there was no room). Installers simply mount the tray to the subfloor using concrete anchors at 4-foot to 5-foot intervals to keep the trays in position. The 101 Series Snake Tray installs faster and requires less manpower than any other option, saving labor costs. All other competitive cable trays require mounting accessories. The patented 101 Series Snake Tray is the only one-piece solution on the market.

Each 101 Series Snake Tray segment is ten feet long and joins to the previous section in under two minutes using a single universal inline connector bolt that also creates a bonded electrical connection to ground the system. The sections nest together for compact shipping and easier handling on the job site. Its open architecture makes loading, adding or replacing cables fast and easy, and the trays themselves can be unanc-hored, repositioned/reconfigured and remounted to the subfloor again and again.

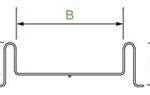

The 101 Series comes in a variety of standard cable loading depths from 2.25” to 4” (A) and widths ranging from 3” to as broad as 21” (B), capable of holding up to 860 Cat6 cables. However, in this case it was clear a customized tray would need to be fabricated due to the sheer volume of low voltage cables and tight space constraints.

The 101 Series comes in a variety of standard cable loading depths from 2.25” to 4” (A) and widths ranging from 3” to as broad as 21” (B), capable of holding up to 860 Cat6 cables. However, in this case it was clear a customized tray would need to be fabricated due to the sheer volume of low voltage cables and tight space constraints.

Snake Tray designed and delivered a shallower 101 Series tray that provided a standard 3.5” cable loading depth (A) in a total vertical space of only 4-1/8” (C). This would allow the low voltage cable pathways to jump over the AC conduits yet remain within the confines of the 6” RAF riser height. No other product can provide a 3.5” cable loading depth in a tray just 4-1/8” tall and still keep the cables off the floor.

Spine & Rib Design

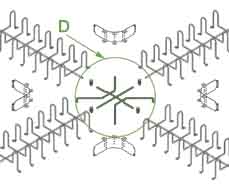

To accommodate the thousands of cables, the 101 Series were organized into double or triple parallel side-by-side pathways for the central trunks, some up to 18” wide. Intersections (D) with snap-on turning fences branched off where needed, seamlessly transitioning to narrower 12”, 6” and eventually 3” trays as the pathways reached their furthest endpoints, bringing cables to floor boxes at individual offices and workstations with minimal materials and cost.

To accommodate the thousands of cables, the 101 Series were organized into double or triple parallel side-by-side pathways for the central trunks, some up to 18” wide. Intersections (D) with snap-on turning fences branched off where needed, seamlessly transitioning to narrower 12”, 6” and eventually 3” trays as the pathways reached their furthest endpoints, bringing cables to floor boxes at individual offices and workstations with minimal materials and cost.

Company policy dictated the use of eco-friendly and energy-efficient construction materials wherever possible, and preferably made in the USA. Snake Tray easily checked these boxes as all products are manufactured in our Bay Shore, New York facility using recycled steel. There is zero waste, no cutting or welding, and little carbon footprint associated with installation as no power tools are required except for attaching the concrete anchors.

Business Outcomes

As a result of using the modified 101 Series Underfloor Snake Tray, the elements associated with finishing floors three, four, five, six, seven, nine and eleven proceeded faster than anticipated, allowing the facility to begin to welcome employees ahead of schedule.

The floors were wired for low voltage data and telecommunications simultaneously, with the 101 Series trays installed immediately after the RAF risers and AC voltage lines were put in place. Total time to completion was approximately 3 weeks for a total of 20,000 linear feet of cable pathways.

Underfloor cable conveyance maintained the aesthetics and neat appearance of the space while bringing connectivity to the point of need with inherent versatility to adapt to new uses.

The electrical contractor selected for the job was the same company that had installed a similar Snake Tray underfloor cable management system at a major financial services group’s new world headquarters, just a few blocks north in midtown Manhattan. Already familiar with the 101 Series and Snake Tray’s highly repeatable installation best practices, electricians were able to hit the ground running. The contractor was able to use fewer skilled workers and saved hundreds of labor hours, reducing costs while completing each floor on or ahead of schedule.

Snake Tray’s proximity to the project meant we could fabricate and deliver tray sections quickly, keeping pace with other aspects of just-in-time building construction. Stacks of hundreds of nested 101 Series trays were loaded onto trucks as they were completed, minimizing shipping costs, fuel consumption and space – critical when transporting materials into Manhattan.

Snake Tray’s proximity to the project meant we could fabricate and deliver tray sections quickly, keeping pace with other aspects of just-in-time building construction. Stacks of hundreds of nested 101 Series trays were loaded onto trucks as they were completed, minimizing shipping costs, fuel consumption and space – critical when transporting materials into Manhattan.

As the building continues to evolve over time, the cost and effort required to reconfigure office space as needed will be minimal as making adds, moves and changes to floor layout will be as easy as lifting RAF tiles to expose cable pathways.

Snake Tray: Your Partner for Customized Underfloor Cabling Solutions

This case study highlights Snake Tray’s ability to conceive, build and deliver one-of-a-kind customized solutions that are available from no other manufacturer. It represents the latest in a long line of successful projects that have grown out of mutual trust and proven performance over a decades-long relationship.

Snake Tray products are designed to drive down the time, labor, and costs of modern building construction. Contact us to learn how we can take the unpredictability out of your next cabling project.