Renewables: More Popular and Bigger Than Ever

Boosting the capacity and reliability of our power grid is a priority for electricity providers, especially given hyper-scale data centers’ insatiable appetite for power. Utilities are increasingly turning to clean energy sources (solar, wind, hydro, geothermal) and battery energy storage systems (BESS) to augment their power generation and distribution capabilities.

As renewable energy efficiencies improve and costs decline – for example, today’s solar panels are cheaper to produce while converting up to 25% of sunlight into electricity, up from 15% ten years ago – utility-scale solar/wind farms are getting more popular and bigger than ever. Some are so large that the arrays and turbine towers must navigate around natural geologic features as well as man-made obstacles and boundaries, resulting in odd layouts and unexpected cabling challenges. No two projects are ever alike.

The Trouble with Trenching

Tackling the cable management aspects of renewable energy plants using traditional trenching methods significantly impacts time and cost and gets more complex as project size increases.

Tackling the cable management aspects of renewable energy plants using traditional trenching methods significantly impacts time and cost and gets more complex as project size increases.

- It is a messy, expensive and time consuming process to dig, lay cables, backfill and regrade trenches for every row of panels. Skilled labor and heavy earth moving equipment are required.

- Unforeseen obstacles – boulders, roots, changing soil conditions, abandoned plumbing lines and weather events – can impede trenching progress.

- Buried cables must step up in ampacity to compensate for the effects of derate: energy lost due to the friction of elections generating heat underground, increasing conductive material costs by an average of 40%.

- The lack of visibility to cables makes pinpointing faults difficult and requires more digging to expose and repair.

Further, prime land adjacent to utility property or within proximity to major population centers is becoming scarcer and more expensive, forcing electricity providers to get creative in where they build. Some are adding solar arrays to rooftops or floating on retention ponds. Others are repurposing sites where trenching is not possible such as capped landfills, former industrial sites, abandoned airport runways, areas with a high water table, uneven/rocky terrain, etc.

For any combination of these reasons, if your next renewable energy client is considering above ground photovoltaic (PV) cable management and/or a Battery Energy Storage System (BESS), you need to consider Snake Tray.

Snake Tray Snake Max: The Trenching Alternative

Snake Tray invented Snake Max® for the express purpose of simplifying high ampacity cable conveyance for high voltage renewable energy plants and BESS installations. The patented Snake Max is the only “free air” cable management system that solves all the problems associated with trenching:

Snake Tray invented Snake Max® for the express purpose of simplifying high ampacity cable conveyance for high voltage renewable energy plants and BESS installations. The patented Snake Max is the only “free air” cable management system that solves all the problems associated with trenching:

- Traverses any type of terrain over any distance

- Faster cable installation, easy visibility to repairs

- Minimizes derate, reduces copper needs by up to 40%

- Requires no digging, attaches to solar panel support structures

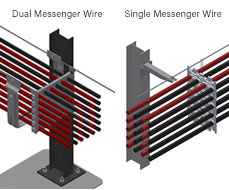

- Single/dual messenger wire and side rail configurations handle any load

- Captures up to 8% more metered energy than buried cables for a faster ROI

Snake Max is the only solution that provides consistent cable support while maintaining end-to-end cable separation equal to at least one cable diameter as mandated by the NEC, removing the need to bundle cables and allowing for natural heat dissipation and maximum energy throughput.

Time = Money

A key benefit of Snake Max is its ability to shorten the cabling time horizon, bringing projects online sooner and generating revenue weeks or months faster than trenching allows.

A key benefit of Snake Max is its ability to shorten the cabling time horizon, bringing projects online sooner and generating revenue weeks or months faster than trenching allows.

The issue is that many clients wait until initial blueprinting is complete before consulting us, or even break ground before realizing trenching is untenable. By then it’s too late to take full advantage of our engineering know-how. The earlier you bring Snake Tray into the design and planning stages of your project, the more value we can add.

Leverage our decades of above ground cable pathway design expertise at no cost. Snake Tray engineers have a keen eye for elements you may not have considered, pitfalls to avoid, plus countless tips and techniques to get your project over the finish line faster at minimal cost.

For example, a topology with a lot of 90° turns and elevation changes calls for cable conveyance with side rails, but that adds to cost. Side rails are also necessary for support when there is no means to anchor messenger wire. Solar farms arranged in long rows or gently curved arcs are generally better served by tensioned messenger wire, a more economical solution. Free air cable conveyance realizes significant savings in conductive materials, and depending upon ampacity requirements, we can help determine whether the load should be supported by dual or single messenger wire systems, potentially saving even more. Snake Tray engineers can help design the best solution given unique site challenges and variables.

Best Cabling Practices for Renewable Energy Plants

Think about these factors when scoping out your next renewable energy project and then reach out to Snake Tray before you commit resources to cabling.

Terrain Evaluation

Is the ground suitable for trenching? Caliche and bedrock may need blasting, sandy/loose soil requires additional boarding and support, while clay can present drainage or water pooling issues. Is the land flat? Peaks and valleys complicate trenching depth. If the site was previously used for agricultural or industrial purposes, there may be pollutants in the soil that could enter the air or water supply.

Snake Max eliminates trenching and boarding, thereby minimizing issues associated with various soil conditions while leaving the earth as undisturbed as possible, limiting environmental concerns.

Tip: Above ground cable conveyance eliminates the need to diagram and mark subterranean cable paths and junction points (which can shift over time due to geologic activity and are never exactly where the map shows).

Cable Count and Ampacity

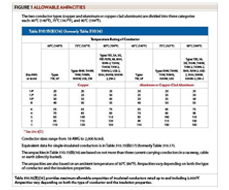

Determine the number of cables needed for each row of panels to carry the expected energy load. Next, perform an ampacity study comparing the cable size required for the load when buried versus free air cable conveyance. NEC Table 310.17 provides guidance for Ampacities of Single-Insulated Conductors in Free Air. In many cases a smaller diameter cable can be used, saving up to 40% in conductive material costs by eliminating the need to account for derate factors due to burial.

Determine the number of cables needed for each row of panels to carry the expected energy load. Next, perform an ampacity study comparing the cable size required for the load when buried versus free air cable conveyance. NEC Table 310.17 provides guidance for Ampacities of Single-Insulated Conductors in Free Air. In many cases a smaller diameter cable can be used, saving up to 40% in conductive material costs by eliminating the need to account for derate factors due to burial.

Snake Max can manage up to 36 cables as large as 1250 Kcmil per run in free air, providing ample capacity for the largest renewable plants while using up to 40% less copper.

Tip: Above ground cable conveyance allows for the use of the smallest diameter conductor possible, so straight line cable runs can be supported by tensioned messenger wire configurations, saving material costs on side rails required to support cable runs navigating several turns and elevation changes.

Operations and Maintenance

Arrays must be spaced sufficiently apart to create access routes for earth moving equipment and personnel during initial construction and subsequent repairs (if buried), and to allow for ongoing landscape maintenance and vegetation control.

Arrays must be spaced sufficiently apart to create access routes for earth moving equipment and personnel during initial construction and subsequent repairs (if buried), and to allow for ongoing landscape maintenance and vegetation control.

Snake Max suspends cables safely off the ground, removing contact with elements that cause faults: burrowing/chewing rodents, lawn mower blades, exposure to constant pressure and moisture from surrounding earth, and corrosion from acidic soil types (sandstone, shale, etc.), extending cable life.

Tip: Above ground cable conveyance reduces O&M costs by allowing for pinpoint fault detection and fast repairs as everything is open to visible inspection, and even permits for natural vegetation control by allowing animals to graze on grasses growing under the arrays.

Solar Plant Topology

There are many ways to bring power from the solar panel to the point of connection: collecting AC power from distributed inverters, aggregating DC power from truck bus systems or distributed DC combiners, stringing home runs to terminations. Will the panels be arranged in straight rows or arcs? Where will the substations be located? These choices are often dictated by obstacles such as rivers and wetlands, highways, rights of way/property lines/setbacks, etc. The presence of streams, rock outcroppings or FEMA flood control zones between subsections, for example, could preclude trenching.

Snake Max is universal, compatible with any type of piling or vertical support post to naturally follow the path of the arrays in any topology, maintaining level cable conveyance even over hilly terrain.

Tip: Above ground cable conveyance provides the flexibility to build on previously unusable sites. Easily map to irregular layouts, elevation changes and navigate around roads, rivers and flood plains to maximize land use.

Design Life and Environmental Factors

Maximize project lifespan with proper material selection given the unique environmental site conditions such as temperature and proximity to the corrosive effects of salt water/ocean breezes. Ensure the cables are hung with the proper balance of tension and slack to account for thermal expansion and contraction without damage, and that the jackets are made from UV-resistant materials to withstand exposure to outdoor elements.

Snake Max uses cable separators (“clicks”) manufactured from high impact polycarbonate material that will outlast the life of any cable it carries. No replacement costs down the line.

Tip: Snake Tray offers above ground cable conveyance systems in a range of anti-corrosive materials (galvanized steel, aluminum, or stainless steel) to meet the demands of any harsh environment.

Leverage Array Infrastructure and Homogenize Parts

One of the easiest ways to reduce cost and time to completion is to multi-purpose other elements of project support infrastructure, in this case using the same supports that hold the solar panels to also support the conveyance. Standardize pile type and support hardware wherever possible to streamline parts inventories, suppliers, and simplify installation for contractors.

Snake Max does exactly that, integrating with any type of metal I-beam or tensioned messenger wire pilings to eliminate the need for a separate suspension system while using standard hardware to attach to support pilings.

Tip: If the project is making use of a specific pile type (driven I-beam, helical screw, etc.) to support the array, Snake Tray engineers will seek to use that same type of pile or screw to support the cable management system. This homogenization of support structures allows for all support to be installed together by the same equipment and/or sub-contractor, saving more time and money.”

Above Ground Cable Conveyance: Come for the Terrain, Stay for Everything Else

Many customers initially come to us seeking a solution to the challenges of trenching after encountering poor terrain conditions, unaware of all the other benefits of above ground cable conveyance.

Upon learning of the additional labor, material and time saving advantages of free air cable management and maintenance – plus the ability to start generating revenues sooner and harvest up to 8% more electricity by eliminating derate – most realize Snake Max is the way to go even if the site was suitable for trenching. And the cycle of repeat customers and successes begins. With Snake Tray, everyone wins!