Older, highly experienced cable installers and licensed electricians are retiring from the Information and Communication Technology (ICT) and Electrical industry at a rapid pace. Combined with the boom in hyperscale data center construction and a lack of apprentice-class talent entering the labor pool, many electrical contracting firms have found themselves at the center of a perfect storm: Too much work and not enough skilled workers.

This is per an article in the December 2025 newsletter on ICT industry trends by Cabling Installation & Maintenance (CIM), an organization devoted to covering the cabling industry and associated trades.

CIM says the impact on electrical contractors is significant. Strong demand for skilled labor leads to higher wages and decreased profit margins. Fewer workers on the job site means overtime to stay on schedule – further inflating labor costs – while lack of experience extends time horizons to project completion as novices learn their craft on the job.

Different Paths to Closing the Construction Skills Gap

Electrical contractors have several choices when it comes to filling the skills gap. They can:

- Continue to pay top dollar (plus overtime) to highly experienced talent in a shrinking labor pool.

- Leverage temporary staffing and employment agencies to fill openings on a per-project or freelance basis. (Typically lower experience).

- Lure new installers and electricians to the industry by offering competitive starting wages and skill-building apprenticeship programs.

- Migrate towards “de-skilled” and premanufactured components and tools that do not require significant experience or intense training to gain proficiency.

Options one, two and three address the problem by throwing more money at it. Option four seeks to reduce costs while maximizing available (read: unskilled) labor. We’ll focus there.

Snake Tray Fills the Construction Skills Gap

In the areas of cable conveyance and power distribution, electrical contractors are turning to manufacturers like Snake Tray for prefabricated, streamlined solutions designed to speed installation, lower costs and shorten time to project completion using less skilled labor. Here’s how:

Application: Low voltage cable management

Snake Tray’s family of patented hand-bendable cable trays allows installers to create turns and navigate around/over any obstacle to create cable pathways in seconds – no tools required! Built-in mounting rings allow for attachment to any vertical or horizontal surface without specialized hardware, accessories or skills. Tray sections attach and bond instantly with a single connector bolt, and their open architecture design speeds low voltage, fiber optic and data cable loading.

Snake Tray offers hand-bendable cable trays for use under raised access floors (101 Series), mounted to walls or suspended from ceilings (201, 401, 454 and 501 Series) and for metal clad (MC) cables (701 Series) in single or dual pocket configurations.

The weatherproof 407 Series is optimized for outdoor and rooftop solar installations, and there’s even a low-profile, multi-pocket version for mass transit power, lighting and signal cabling called Snake Rack® that follows the curve of subway tunnels.

Takeaway: If your installers can use a drill and a screwdriver, they can install Snake Tray cable management systems!

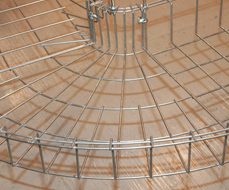

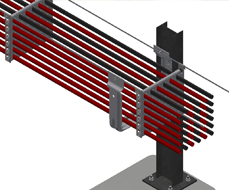

Application: High capacity cable management

The 801 Series Mega Snake® basket tray handles heavier loads of low and high voltage cables yet is lightweight and easy to install. Constructed from ¼” stainless steel rods, Mega Snake is as strong as a steel ladder at a fraction of the cost.

Premanufactured turns, Tee’s, and intersections eliminate hours of labor-intensive cutting and grinding while maintaining proper bend radii. Novice installers can connect bonded basket tray sections in under one minute, while its built-in suspension system eliminates the need for brackets and struts. Installers simply hang tray sections from threaded rods and connect turns, make elevation changes and attach accessories (camera mounts, patch panels, cable dropouts, etc.) as needed – even add tiers to increase capacity or separate high from low voltage runs.

Check out this video comparing the five-minute process to install a prefabricated Mega Snake turn versus the hour-long process to cut, grind and bend a straight section of generic wire basket into an NEC-compliant 90° sweep.

Takeaway: Technicians can complete installations faster and reduce costs by eliminating on-site fabrication tasks required by other basket tray systems – no advanced welding skills required!

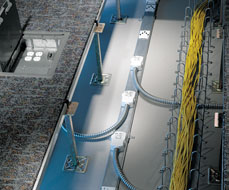

Application: Under raised access floor (RAF) cable management

Environments like data centers, trading floors, call centers and casinos rely on underfloor cable conveyance to safely run data, telecommunications and power lines to their terminations.

The 301 Series Snake Canyon® is the fastest, easiest way to create concealed cable pathways. Designed to integrate with any type of 2’ x 2’ RAF, Snake Canyon leverages the existing structural elements of the pedestal support system. Installers simply lift a floor tile and drop a 301 Series basket tray section into place. Trays can be moved and reused as needed. Under floor air flow is maintained, and access to the cable plant for additions or repairs is easy.

Takeaway: Save on skilled labor and time with Snake Canyon. There’s no specialized hardware, tools, or on-site fabrication needed to install the 301 Series, a simple twisting cam-loc holds each basket securely in place.

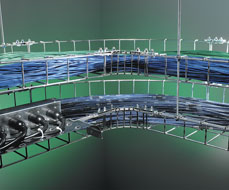

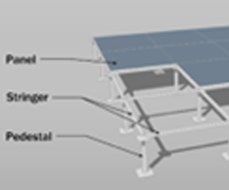

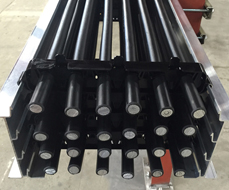

Application: High ampacity/DC solar cable management

Moving outside, there is no better system to manage volumes of high ampacity DC cables than Snake Tray’s above-ground, free-air Snake Max™.

Available in single and dual messenger wire configurations, or hard rails models, Snake Tray offers versions optimized for utility-scale solar plants, battery energy storage systems (BESS), floating solar arrays on utility retention ponds, EV charging stations, and even for wind turbines and fuel cells. Whatever the energy source, Snake Max transports current at its highest possible throughput rate without trenching, digging or suffering from derate.

Installers connect messenger wire or hard rails to piles driven into the ground. Using Snake Max’s patented system of bridles and clicks, installers can lay up to 10,000 feet of cable per day. Snap-together components require no tools or field fabrication, speeding project completion while maintaining NEC-compliant cable separation over the entire run.

Takeaway: Snake Max eliminates the need for earth moving equipment and associated labor, while loading cables into each layer can be handled by installers with little experience and in less time than trenching!

Application: Under floor power distribution

Snake Tray’s prefabricated Snake Bus® power distribution system is the fastest, easiest and most cost-effective way to wire commercial spaces up to 1,000,000 square feet for electricity beneath raised access floors.

Rather than highly paid electricians spending weeks attaching a web of conduit and risers to the subfloor, fishing copper through pipes and manually stripping wires to connect to fixtures and outlets, Snake Bus allows non-skilled technicians to create a 3-phase, 18 kW power distribution system in a matter of hours.

Snake Bus® is an alternative to traditional pipe-and-wire underfloor power systems, designed to reduce complexity while improving adaptability over the life of the building. The system delivers up to 18kVA of power directly to user locations using modular, plug-and-play components installed beneath raised floors. It is well suited for office environments, education facilities, operations centers, and production spaces—particularly where layouts are expected to evolve over time.

Tap offs (Snake Whips) bring electricity to the RAF surface by connecting recessed floor boxes to receptacles positioned every 12 inches along the track. Snake Bus installs in record time and tracks can be easily moved and reused over and over to accommodate changes in floor layout.

Takeaway: If your installers can snap two pieces of interlocking track together, fire a nail gun into the subfloor to secure it in place, and plug an outlet into a receptable, they can install a Snake Bus power distribution system!

Prefabrication is the Answer

At a time when the cost and availability of highly skilled electricians can make or break a project, the answer is not more laborers, but rather pre-manufactured and modular solutions that can be used by less skilled workers without suffering a drop in quality or productivity.

All Snake Tray products are designed to do just that: install quickly, reduce skilled labor and material costs, and significantly drive down the total cost and time of construction. Visit us at snaketray.com to learn more about how Snake Tray can help fill your skills gap!